The Popularity of Zirconia Cearmic Blade

Zirconia Ceramic blades are becoming popular in recent years for its extremely high cutting edge strength and excellent flexural strength and hardness. The blade is made by sintering zirconia powder at high temperatures, which make it a dense homogeneous material with high hardness and sharpness. Zirconia Ceramic is known for its toughness, compressive strength and thermal shock resistance. Besides zirconia, it can also use ceramic like Alumina, Silicon Nitride and Boron Nitride. But material zirconia is more common.

Why It is Becoming Popular

Compared with traditional blade like steel or diamond blades, Zirconia ceramic blade has the advantages of high durability, sharpness and high level of chemical resistance. It is resistant to wear and tear, so it can be used for a long time. This makes it a cost-effective option for business.At the same time it can be sharpened to a fine edge, which makes it ideal for cutting application.

Here is the Properties of Zirconia Ceramic

| Properties | Unit | Value |

| Main Composition | % | ZrO2 |

| Density | g/cm3 | ≥6.0 |

| Vickers Hardness | kg/mm2 | 1,200.00 |

| Rockwell Hardness | HRA | 88 |

| Modulus of Elasticity | GPa | 220 |

| Bending Strength | MPa | 2,500.00 |

| Fracture Toughness | Mpa.m1/2 | 10 |

| Compressive Strength | MPa | 2,500.00 |

| Melting Point | ℃ | 2,850.00 |

| Thermal Conductivity (In 25℃) | W/m.k | 1.5~2 |

| High Temperature Resistant | ℃ | 1000 |

Zirconia Ceramic Blade VS Traditional Metal Cutting Blades:

Never rust like metal blades

Good electrical insulation

Good corrosion resistance to acids and alkali

High temperature resistance

Sharpness of cutting edge will remain 60 times longer than steel blades

Where We Can Use Zirconia Ceramic Blade

The range of applications for zerconia ceramic blade in industry as below:

- Medial

- Aerospace

- Automotive

- Paper

- Semiconductor

- Chemical Fibers

- Firm and Foil

- Fiberglass

- Textile Industry

- Food and beverage production

Here we would like to introduce its use in the industries of medical, aerospace, and automotive. In medical industry, zirconia ceramic blade is used for surgical procedures, such as cutting bone or tissue. It is also used for dental applications, such as cutting crowns or implants. In aerospace industry, zirconia ceramic blade is used for cutting composites that are difficult. They are also used for precision cutting of components for aircraft engines and other critical parts.

In the automotive industry, ceramic zirconia blade is used for cutting and shaping brake pads, clutch plates, and other components that require precision and durability.

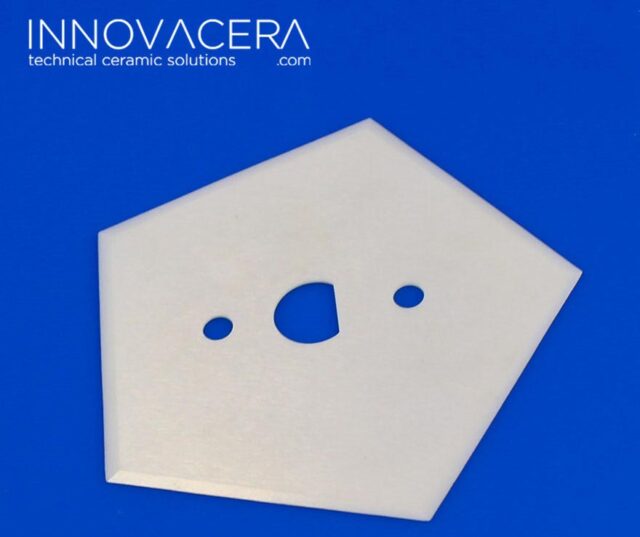

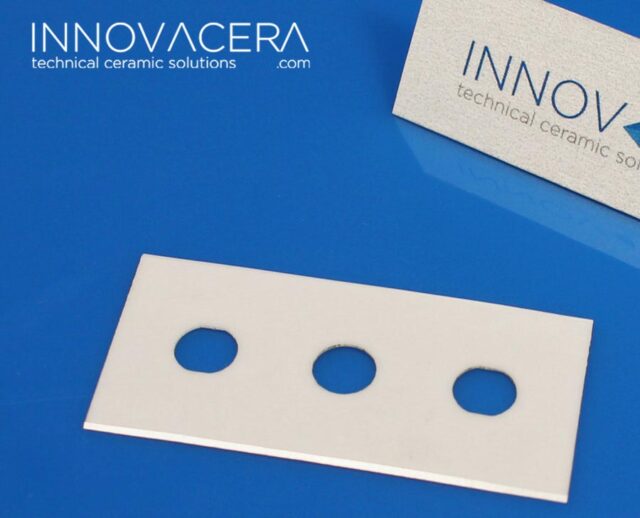

Example of Standard Shape and Size

1. 3 hole pentagon shape with size 62.32*0.2mm

2. 3 hole Rectangular shape with size 43*22*0.3mm

Besides above standard size and shape, we can also do the customized one to meet your specific size and shape requirements.

Innovacera has developed a high-performance zirconia ceramic for cutting yarns, textiles and other industry. It stands out from other materials with its extremely high cutting edge strength and excellent flexural strength and hardness. If you have the need, feel free to contact us.

Enquiry

Enquiry