According to the substance used in their sensitive element, are:

Zirconium (zirconium oxide)

Titanium (titanium oxide)

Wideband

According to their design:

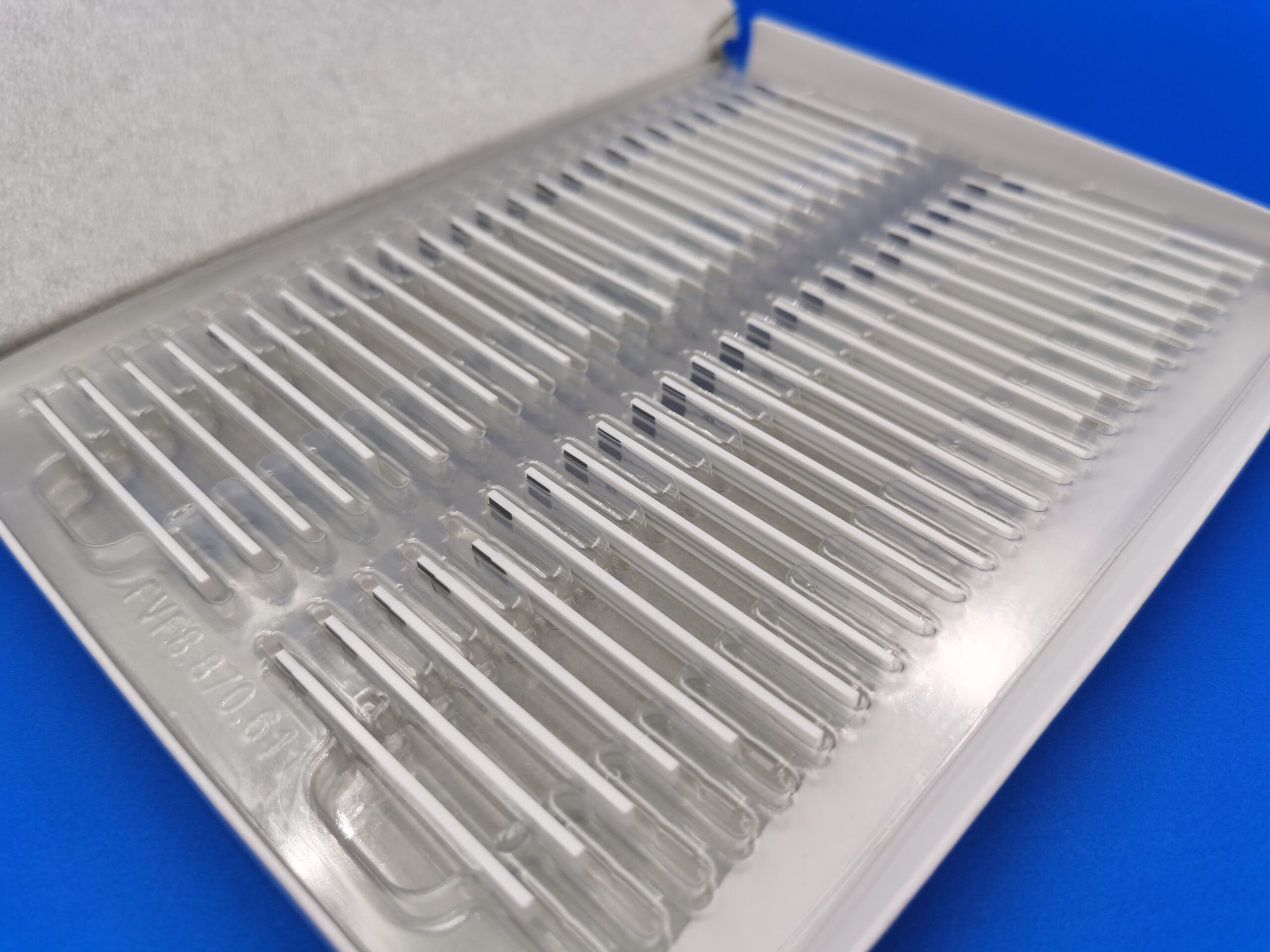

Single-wire lambda sensor

Two-wire lambda sensor

Three-wire lambda sensor

Four-wire lambda sensor

Single-wire lambda sensor was used in the early injection systems with feedback (lambda regulation). It has only one terminal, which is the signal terminal. Sensor ground is its housing and it connects to the engine ground through the exhaust pipes.

Two-wire lambda sensor has a separate grounding cable. It was used in the early injection systems with feedback (lambda regulation) also.

The disadvantage of the single-wire and the two-wire sensors is that their operating temperature range starts at 300 ºC. The sensor will not work and will not produce a signal until this temperature is reached. It was necessary for the sensor to be mounted as close to the engine cylinders as possible in order to heat and wrap from the hottest exhaust gas stream. The process of heating the sensor slows down the regulation process of the onboard controller because of the feedback. In addition, using the exhaust pipe as a signal ground requires the sensor’s thread to be coated with a special electrically conductive paste, which increases the possibility of a bad contact in the feedback circuit.

Types of oxygen sensors

In the three-wire lambda sensors, is a special heating element inside which is constantly turned on when the engine is working and thus it’s reducing the heating time of the sensor to the working temperature. This allows the installation of the sensor on the exhaust manifold, near the catalytic converter. The disadvantage is the need for electrically conductive grease.

In the four-wire oxygen sensors – two of the terminals are the heater terminals and the other two, are the signal termina

If you want to know more, pls contact us.

Enquiry

Enquiry