Boron nitride atomizer nozzles for powder metal atomization play a crucial role in the atomization process. These nozzles are responsible for converting molten metal into fine powder particles, which are then used in various industries such as automotive, aerospace, and electronics.

There are different types of boron nitride atomizer nozzles used in powder metal atomization, including gas atomizers and water atomizers. Gas atomizers use high-pressure gas to disintegrate a molten metal stream into tiny droplets, which solidify into powder particles as they cool down. Water atomizers, on the other hand, use water jets to break up the molten metal stream into powder particles.

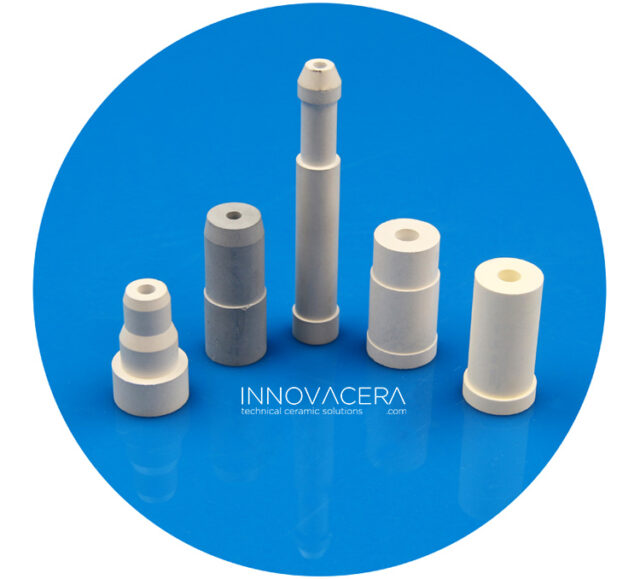

The design and construction of boron nitride atomizer nozzles are critical for ensuring efficient and effective atomization. Some key factors to consider in boron nitride atomizer nozzle design include:

Nozzle geometry: The shape and size of the nozzle play a role in determining the droplet size and spray pattern. Different geometries can be used to achieve specific particle size distributions.

Nozzle material: The material used to construct the nozzle should have high toughness and resistance to wear and corrosion. Common materials include stainless steel, tungsten carbide, and ceramic.

Nozzle cooling: Atomizer nozzles need to withstand high temperatures, and cooling mechanisms such as water jackets or internal channels can be used to prevent overheating.

Nozzle alignment: Proper alignment of atomizer nozzles is crucial for achieving consistent powder particle size and distribution. Precision alignment systems are employed to ensure accurate positioning of the nozzle during atomization.

Boron nitride atomizer nozzles are typically custom-designed to meet specific requirements, such as the desired powder particle size range and production capacity. Advanced manufacturing technologies, such as additive manufacturing, are now being used to produce atomizer nozzles with complex geometries and improved performance.

Boron nitride atomizer nozzles are key components in powder metal atomization, enabling the production of high-quality powder particles used in a wide range of applications.

Enquiry

Enquiry