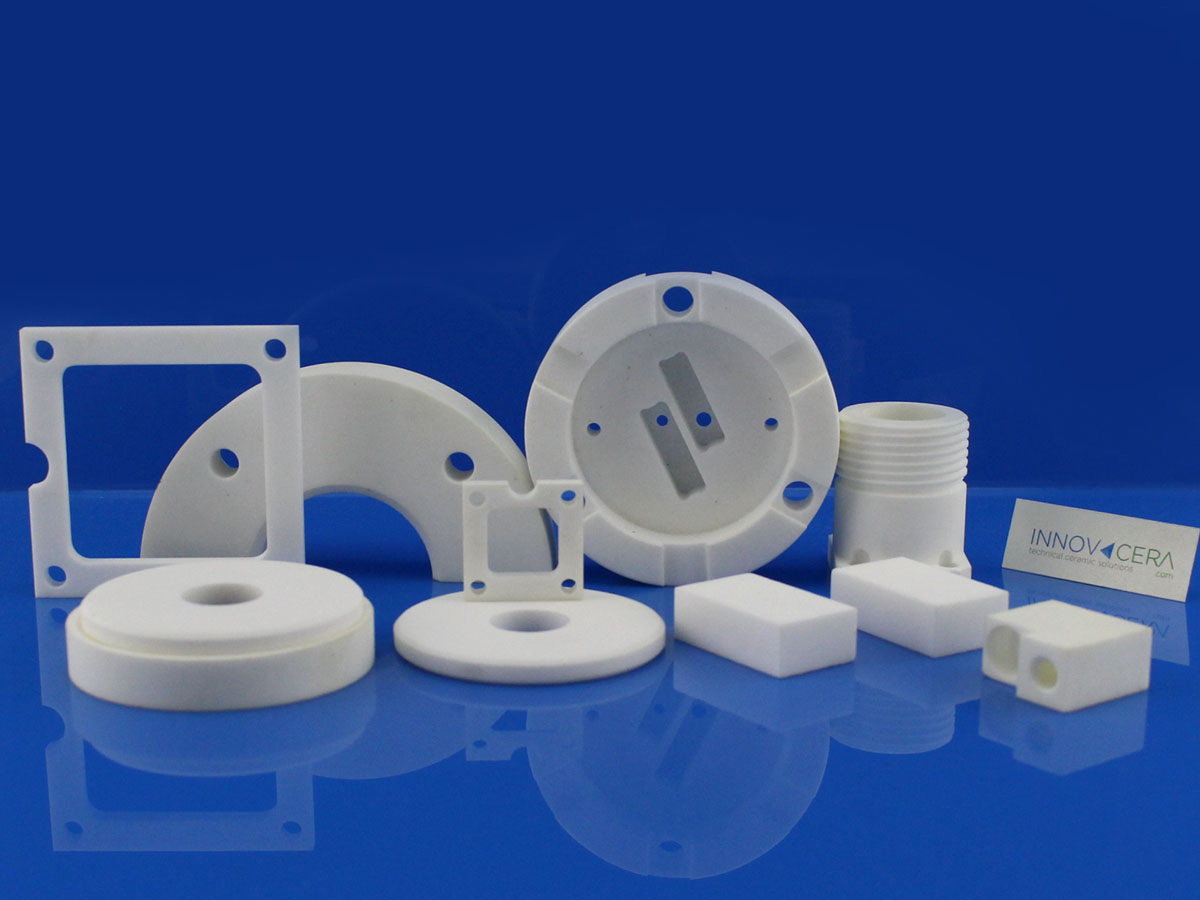

Machinable Glass Ceramic is a mica glass ceramic material with a unique combination of properties. It is easily machinable using conventional metalworking tools, with no post-firing required. A versatile ceramic material with technical strength and insulation properties exceeding high-performance plastics, it is also stable in high temperatures (continuous at 800° Celsius, up to a peak of 1,000° Celsius) with 0.0069% porosity. The ceramic material also acts as an electrical insulator that is radiation resistant and has low thermal conductivity.

Machinable Glass Ceramic

Characteristics include:

1.0.0069% porosity and non-shrinking

- High dielectric strength

- Electrical resistivity

- Withstands high temperatures up to 800ºC

- Tight tolerance capability

- Easily and economically machined into complex shapes and precision parts

Applications include:

- Feedthroughs

- Hermetic seals

- Insulators and supports for vacuum environment feed-throughs

Spacers, headers, and windows for microwave tube devices

- Aerospace components

- Welding nozzles

7. Fixtures

Enquiry

Enquiry