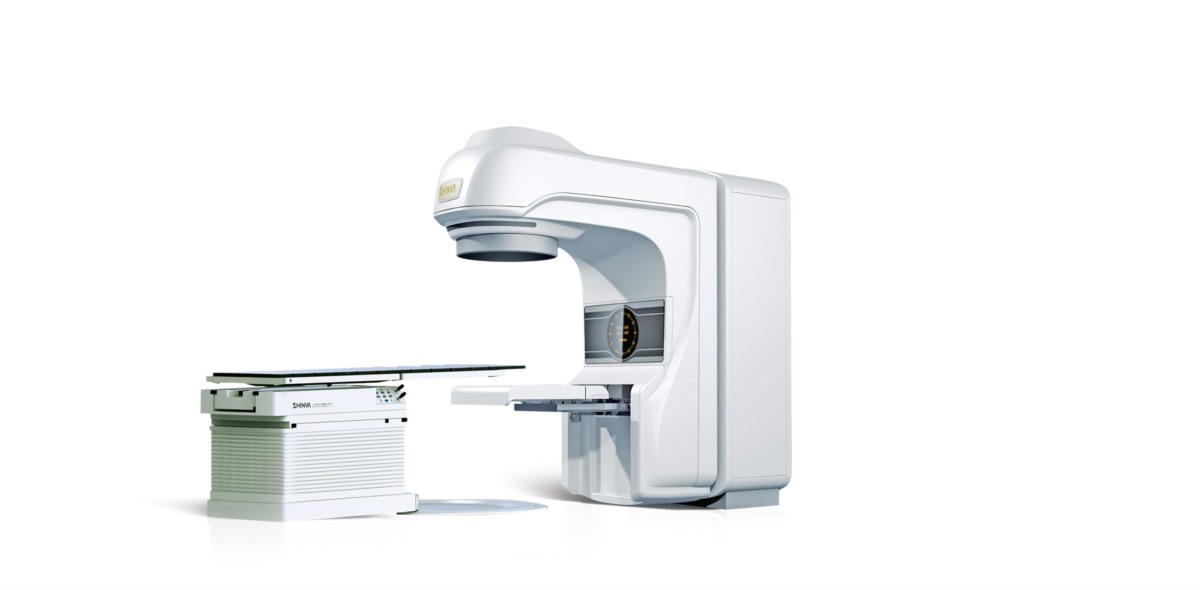

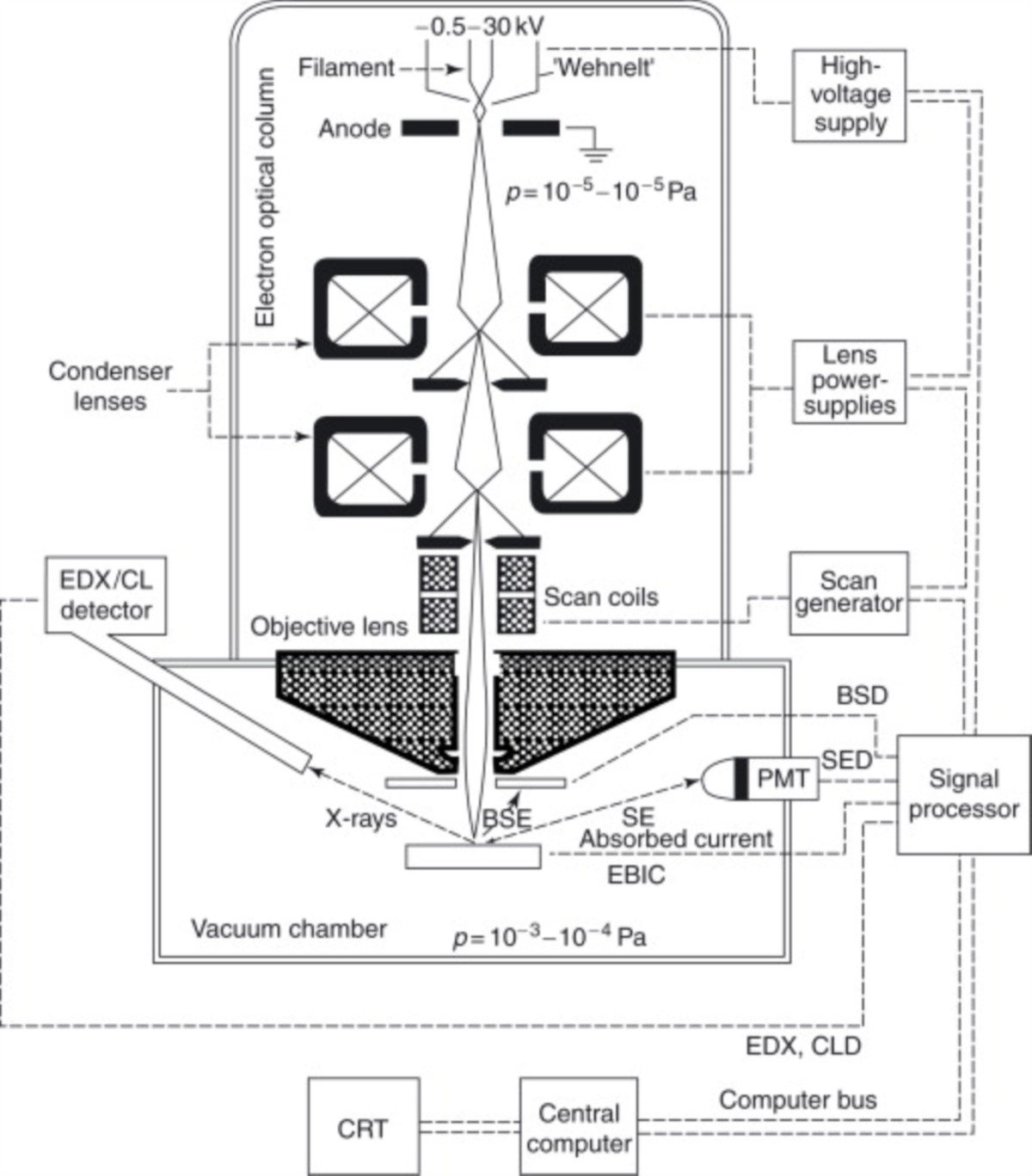

Electron beam (EB) accelerator is an advanced devices that utilize electromagnetic fields to accelerate high-energy electrons to the approximate speed of light. These accelerated electron beams are used in a variety of industrial and scientific applications, including materials processing, sterilization, medical radiation therapy, and scientific research. EB accelerators consist of an electron gun that emits the electrons, a series of electromagnetic components (e.g., oscillating chambers and magnets) that accelerate and focus the electrons, and a target or beam exit that directs the high-energy beam of electrons to its intended destination.

Electron Guns are devices that emit electrons using thermal energy or field emission mechanisms, such as tunnelling or Schottky effects, for applications like X-ray chemical analysis and electron backscatter diffraction. In electron beams, electron guns are used to accelerate charged particles. It mainly made of cathode, focusing pole, anode composition.

The cathode is one of the key components of the electron gun, which determines the launch capability and life of the electron gun. At present, the cathode of the electron gun used in the electron linear accelerators in the world is in various forms, which can be summarized in two ways of division:

Direct thermal cathode mostly adopts pure tungsten as cathode material, and the heating current passes through the cathode directly. Interthermal cathode is generally used to lay thoriated tungsten, lay oxide, scandium salt, lanthanum boride, which is divided into bombardment type and heating type.

The whole electron gun are metal-ceramic brazing assembled, which has good insulation, airtightness and firmness, and the ceramic surface is specially treated to prevent high-voltage creepage ignition.

Innovacera has rich experience in metal-ceramic brazing and introduced advanced technical talents. The main materials are 95%~99.5% alumina ceramics, metals such as stainless steel, Kovar, chrome-nickel alloys, etc., the solder used for soldering is silver-copper alloy, pure silver, pure gold and other materials according to the customer’s working condition. The gas tightness of the assembled parts is tested with helium leak detector at 1*10-8~-11 Pa-m3/s.

Come to get more detailed information with your designed drawing!

Enquiry

Enquiry