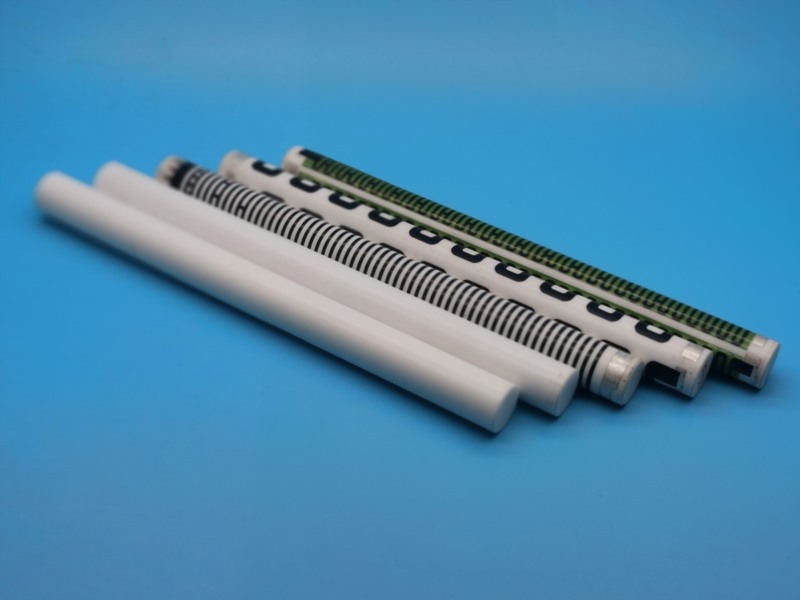

High voltage resistors are essential components in electronic circuits where precision, reliability, and safety are paramount. Among the various types of materials used for high voltage resistors, ceramic cores stand out for their exceptional properties and suitability for demanding applications. Generally the high voltage resistor ceramic cores material is alumina ceramic and it can used as alumina ceramic heater.

Characteristics of Ceramic Cores

Ceramic cores used in high voltage resistors are typically composed of a blend of ceramic materials and metal oxides, carefully formulated to achieve specific electrical and mechanical properties. Key characteristics include:

High Dielectric Strength: Ceramic materials inherently offer high dielectric strength, allowing resistors to withstand high voltages without electrical breakdown or insulation failure.

High Stability: They provide excellent stability over a wide range of operating temperatures and environmental conditions, ensuring consistent performance in critical applications.

Low Temperature Coefficient: Ceramic cores can be engineered to have a low temperature coefficient of resistance (TCR), minimizing variations in resistance values due to changes in temperature.

Mechanical Robustness: Resistant to physical damage and stress, ceramic cores maintain structural integrity under mechanical load, vibrations, and thermal cycling.

Advantages of Ceramic Core High Voltage Resistors

Reliability: Ceramic cores contribute to the overall reliability of high voltage resistors by maintaining stable electrical characteristics over time, reducing the likelihood of failure or performance degradation.

Precision: They allow for precise control of resistance values and tolerance levels, critical for applications requiring accurate voltage division and current limiting.

Compact Design: Alumina Ceramic materials enable the production of compact resistors suitable for densely packed electronic assemblies, saving space and enhancing circuit design flexibility.

Wide Operating Temperature Range: High voltage resistors with ceramic cores can operate effectively across a broad temperature range, from extreme cold to high heat environments, making them versatile for diverse industrial and automotive applications.

Applications in Various Industries

Ceramic core high voltage resistors find extensive use across several industries:

Power Electronics: In power supplies, inverters, and converters, where reliable voltage regulation and current limiting are essential.

Medical Equipment: Used in high voltage power supplies for medical devices, ensuring safe and precise operation.

Industrial Automation: In motor controls, robotics, and industrial machinery where high voltage components must withstand rigorous operating conditions.

Telecommunications: Found in communication equipment, antennas, and transmission systems requiring stable performance in varying environmental conditions.

Manufacturing and Design Considerations

The manufacturing of ceramic core high voltage resistors involves advanced techniques such as precision mixing of ceramic powders, shaping, and firing at high temperatures to achieve the desired electrical and mechanical properties. Design considerations include selecting appropriate ceramic materials, electrode configurations, and protective coatings to optimize performance and longevity.

Ceramic cores play a critical role in the development of high voltage resistors, offering superior electrical properties, mechanical robustness, and reliability.As technology advances and demands for efficiency and reliability grow, ceramic core high voltage resistors continue to evolve, meeting the stringent requirements of today’s power electronics and industrial sectors.

Enquiry

Enquiry