Introduction:Magnesium oxide partially stabilized zirconia with magnesium oxide (MgO) as the stabilizer of zirconia, after forming the crystal structure for a cube, more stable. Magnesium zirconium has better resistance to high temperature and moisture because it is not affected by phase migration.

- What is magnesium oxide partially stabilized zirconia ceramics

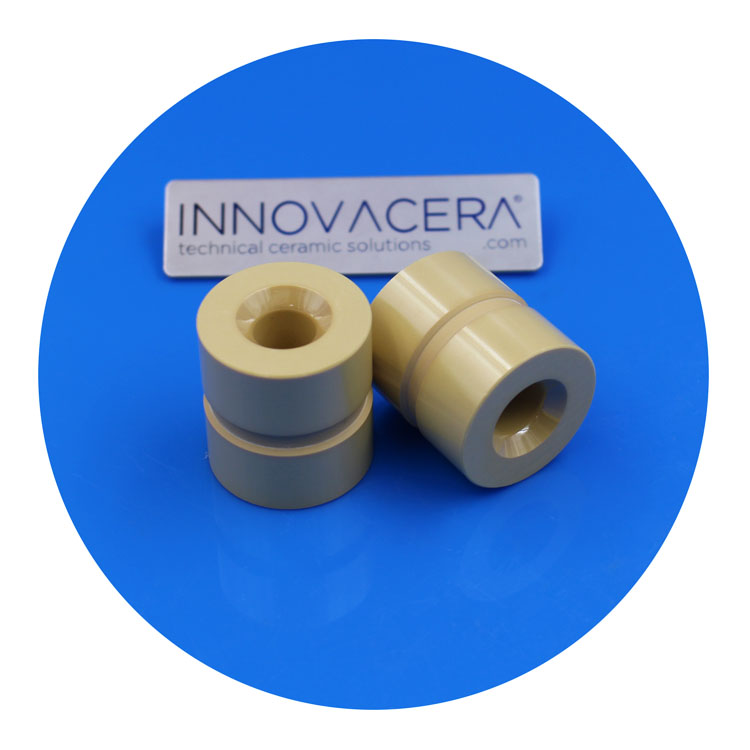

The oxidase-partially stable zirconia ceramics (MG-PSZ), which is commonly referred to as magnesium-zirconia ceramics, are all yellow with a density of about 5.7g/cm³.

Magnesium oxide partially stabilized zirconia with magnesium oxide (MgO) as the stabilizer of zirconia, after forming the crystal structure for a cube, more stable. Magnesium zirconium has better resistance to high temperature and moisture because it is not affected by phase migration. Magnesium zirconium retains its strength even in humid, high temperature environments where the mechanical properties of zirconia begin to deteriorate.2. Advantages and disadvantages of magnesium stabilized zirconia ceramics

- Advantages and disadvantages of magnesium stabilized zirconia ceramics

Magnesium oxide partially stabilized zirconia has the outstanding advantages of excellent mechanical properties and creep resistance at relatively high temperatures. However, the research and development of magnesium stabilized zirconia is restricted by two adverse factors: one is that the solution temperature of magnesium oxide in the cubic zone of zirconia is very high, resulting in magnesium stabilized zirconia is not easy to completely sintering; First, when zirconia is higher than 1000℃, magnesium oxide is easy to produce crystal phase separation and a large number of tetragonal phase instability, which makes the material properties decline and seriously restricts its application in high temperature region.

3.Application

- Wire forming/drawing mold;

- Precision in high-wear environments;

- Axis;

- furnace treatment tube;

- Wear pad;

- thermocouple protection tube;

- sand blast nozzle;

- Refractory materials;

- Furnishing crucible;

- Knives and blades;

- fuel cell parts;

- Bearings and rollers;

- Weld nozzles and pins;

- Gas igniter;

- Electric insulator;

- Ceramic guide plate;

- Oxygen sensor;

- Mechanical seal;

- Performance

| Magnesium partially stabilized zirconia | |||||

| Mechanical property | thermal property | electrical property | |||

| Color | Yellow | maximum service temperature(°C) | 1000 | dielectric constant | 28 |

| Density

(g/cm³) |

6.05 | thermal conductivity@25°C | 2.2 | dielectric strength(6.35mm) | 9.4 |

| Vickers hardness Gpa) | 12.5 | linear coefficient of thermal expansion (40 - 400℃, × 10^ -6/℃) |

10.2 | dielectric loss | 10 x 10^-4 |

| compressive strengthc

(Mpa) |

2100 | Specific heat(J/(kg ・ K) | 400 | volume resistance @25°C |

>10^12 |

| flexure strength (Mpa) |

850 | thermal shock resistance(°C) | 350 | volume resistance @500°C |

>10^3 |

| Fracture Toughness (Mpa·m1/m2) |

4~5 | ||||

| Young modulus (Gpa) |

200 | ||||

| Poisson’s ratio | 200 | ||||

- Note: Performance may vary depending on the batch

Zirconia Partially Stabilized Zirconia Ceramics (Mg-PSZ)

Any more information about advance materail, Click website …..

Enquiry

Enquiry