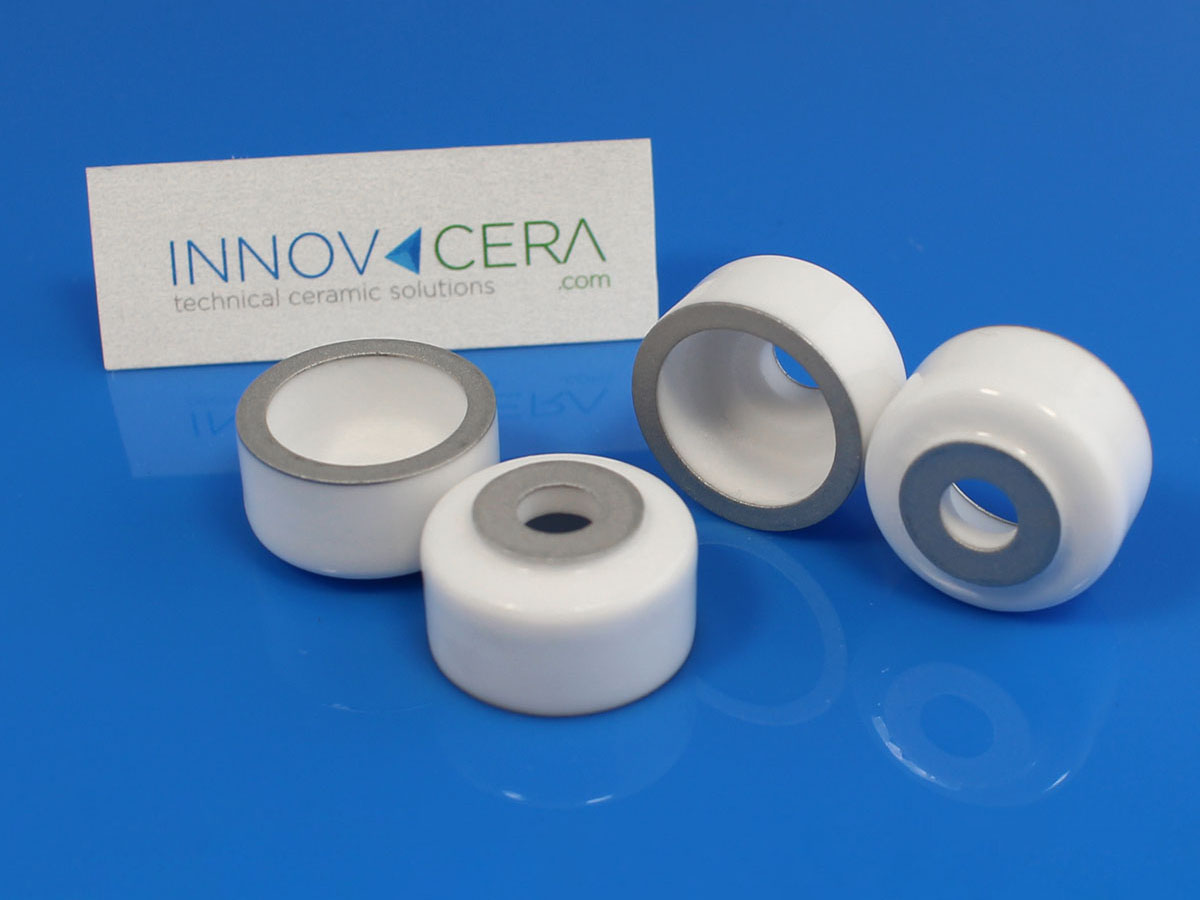

Ceramic metallization is a process in which a layer of metal is deposited onto the ceramic surface to provide a wettable surface for subsequent brazing.

INNOVACERA metallizes precision ceramic components for use in power grid tubes, vacuum interrupters, and similar applications. Our metallized parts are used in critical assemblies brazed by our in-house team or by other brazing suppliers and OEMs. Our metallization creates a strong and robust bond to many different ceramic bodies and has nearly universal applicability for ceramic to metal brazing.

Benefits:

♦ Strong, robust bond

♦ Minimal substrate deformation

♦ Universal applicability for ceramic metal joining

♦ High processing speeds

♦ Uniform coating, thickness, and density

Enquiry

Enquiry