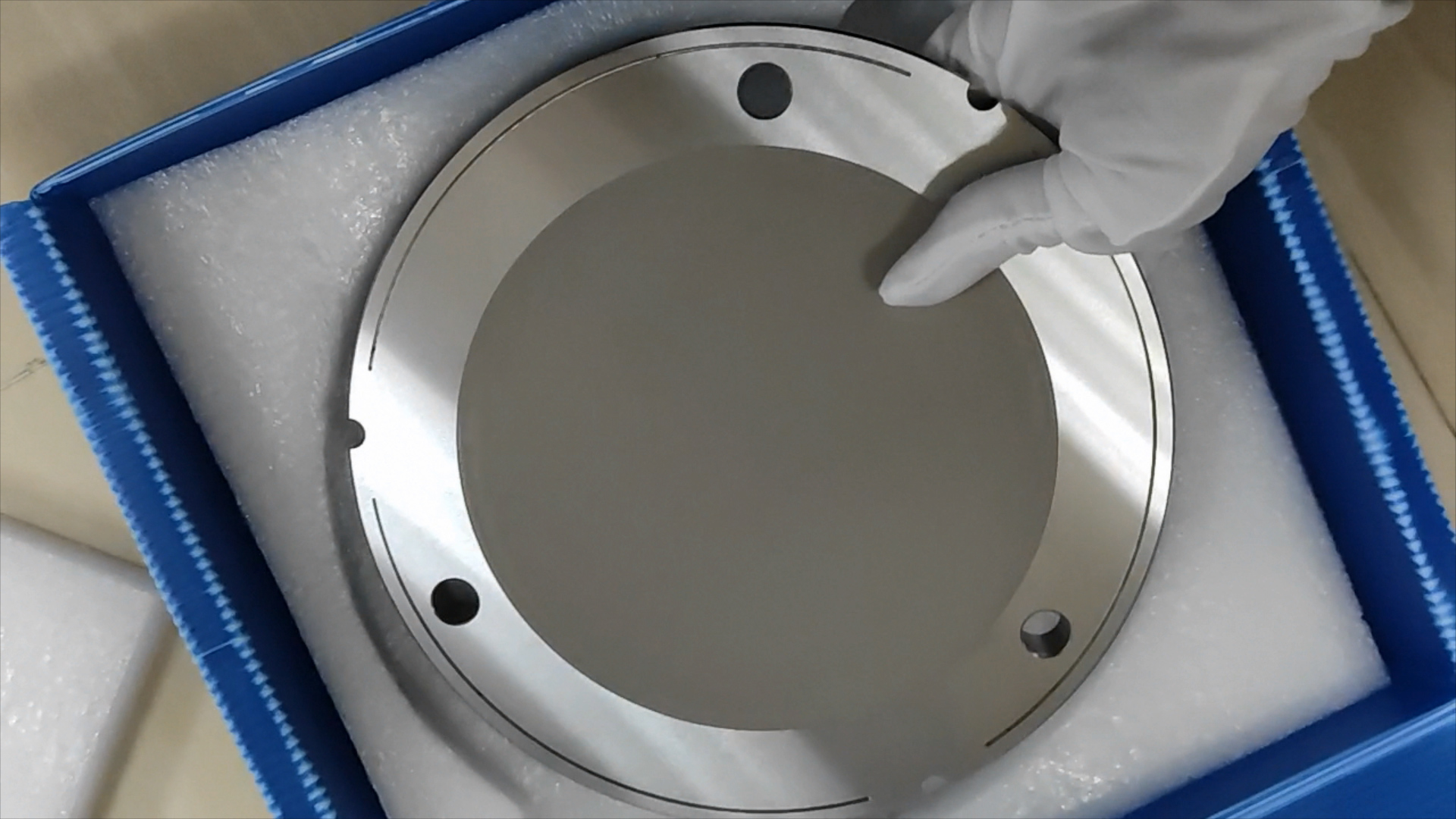

Vacuum chucks are used in the thinning, dicing, cleaning, handling, and other processes of semiconductor electronic chips, like wafers. Why choose microporous ceramic vacuum chucks?

1. During the polishing and cleaning process of wafers, polishing liquid and water mist enter the working table, causing corrosion. And the microporous ceramic vacuum chucks resist corrosion.

2. The microporous ceramic vacuum chuck has no environmental pollution such as light, heat, and electromagnetic, unlike the rubber or other materials vacuum chuck. And the rubber or other materials vacuum chuck will be in direct contact with the surface of the item, so it is very easy to wear.

Therefore, the porous ceramic has high temperature resistance and chemical corrosion resistance, light structure, and electrical insulation. So it is the best choice for vacuum chuck.

3. With its special porous structure, the microporous ceramic has very small holes and can be machined to very precise flatness. Combined with the special air channel design, when a certain negative pressure is given, the wafer can be smoothly and stably adsorbed on the vacuum chuck, so as to avoid wafers that will cause scratches and dents on the surface.

Through the coordination of the focus point and suction force of the vacuum suction cup, wafers of different sizes can be adsorbed on the same ceramic surface.

4. The microporous ceramic vacuum chuck can be reused after regrinding, thereby improving the utilization rate of materials.

Inspection Video:

Enquiry

Enquiry