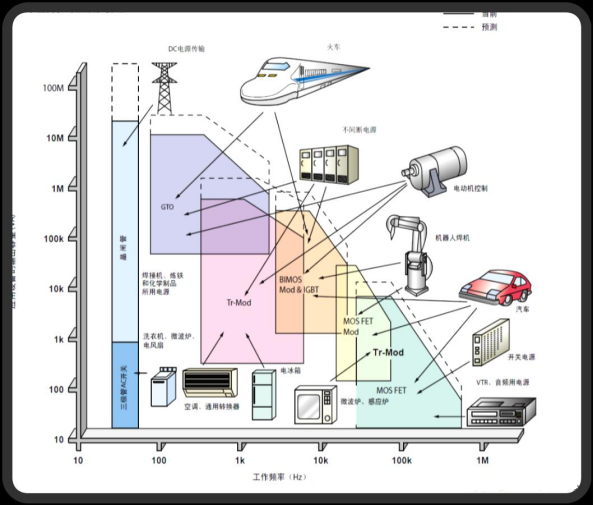

With the development of the electric components, smaller but better performance and lower energy cost elements are pressing demand. The high dense, high power, and a high-frequency component may generate as much as 100W/cm2 heat, such as high bright LED, MOSFET, IGBT, and laser elements. The longer those elements work, the more the heat accumulated. Due to the limited room in the package, if the heat could not have been diffused in time, it would highly affect the elements’ life, performance, and reliability. So, it is important to introduce a good cooling package design and high thermal conductivity ceramic materials into these industries.

Different applications in general

- High brightness high power LED

- Microwave wireless communication and semiconductor equipment

- Automobile

- Energy

- IGBT Module

- IPM Module

Enquiry

Enquiry