Due to its high thermal conductivity (≥170W/m.k), aluminum nitride ceramic crucibles can be used for heat conduction to achieve heating effects, and are widely used in electronic equipment, such as gas atomization of electronic devices.

Aluminum nitride crucibles can also be used as containers for vacuum evaporation and metal smelting, especially suitable for vacuum evaporation crucibles for aln.

Because aluminum nitride ceramics are heated in a vacuum with low vapor pressure and will not pollute aluminum even if they decompose.

In the semiconductor industry, using an aluminum nitride crucible instead of a quartz crucible to synthesize arsenide can completely eliminate the pollution of Si to GaAs and obtain high-purity products.

Aluminum Nitride Ceramic Crucibles

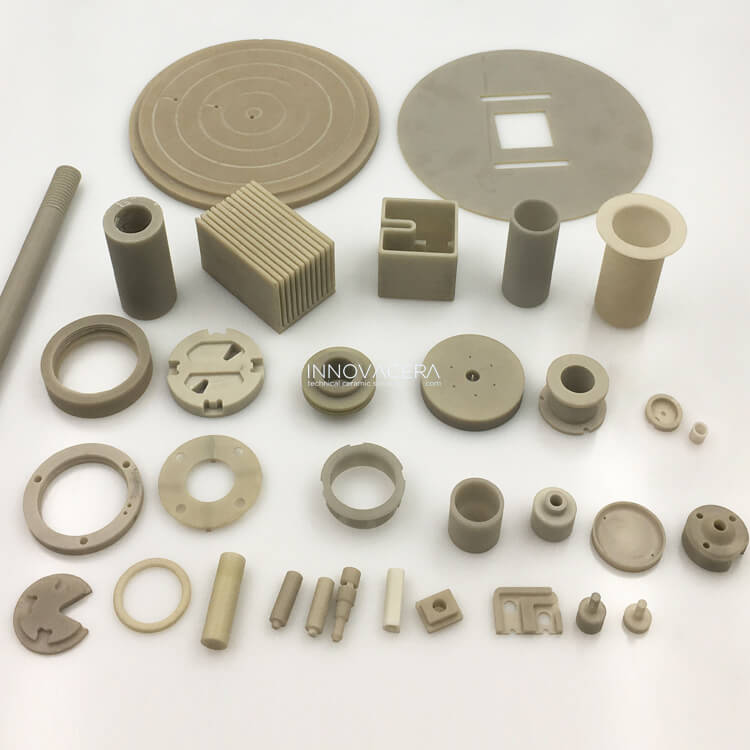

Other Typical Applications of Aluminum Nitride Ceramics

1. Application of optical communication devices

2. Dedicated refrigerator

3. LED industry

4. Automotive electronic modules

5. High efficiency power module

6. High-frequency microwave applications

Enquiry

Enquiry