Compared with other ceramic materials, AlN has a thermal expansion coefficient that matches silicon and excellent thermal conductivity, which makes it more suitable for use in the electronics industry. Aluminium Nitride Ceramic Material Properties is as bleolw.

| Properties | Unit | Value |

| Color | – | Dark Gray |

| Main Content | % | 96% ALN |

| Bulk Density | g/cm3 | 3.335 |

| Water Absorption | % | 0 |

| Flexural Strength | MPa | 382.7 |

| Dielectric Constant | MHz | 8.56 |

| Coefficient Linear Thermal Expansion | /℃,5℃/min, 20~300℃ | 2.805×10-6 |

| Thermal Conductivity | 30 Degree Celsius | ≥170 |

| Chemical Durability | mg/cm2 | 0.97 |

| Thermal Shocking Resistance | – | No cracks |

| Volume Resistivity | 20 Degree Celsius (Ω·cm) | 1.4×1014 |

| Dielectric Strength | KV/mm | 18.45 |

| Surface Roughness Ra | μm | 0.3-0.5 |

| Camber | Length ‰ | ≤2 |

Aluminum nitride can also be used in heat exchangers, crucibles, protective tubes, casting molds, piezoelectric ceramics and films, thermally conductive fillers, etc. Below is some application of Aluminum nitride ceramic components.

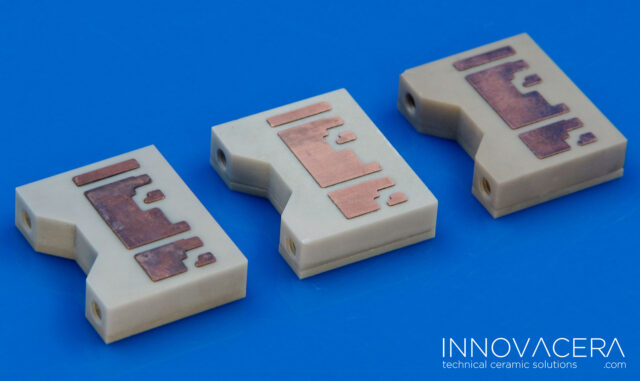

1. Heat dissipation substrate and electronic device packaging

Heat dissipation substrates and electronic device packaging are the main applications of AlN ceramics. Aluminum nitride ceramics have excellent thermal conductivity, thermal expansion coefficient close to silicon, high mechanical strength, good chemical stability, and are environmentally friendly and non-toxic. It is considered an ideal material for a new generation of heat dissipation substrates and electronic device packaging, and is very suitable for hybrid power switches. It is a material for packaging and microwave vacuum tube packaging shells, and is also an ideal material for large-scale integrated circuit substrates.

2. Structural ceramics

Electrostatic chucks for wafer processing are a common structural ceramic application. Aluminum nitride structural ceramics have good mechanical properties, high hardness, better toughness than Al2O3 ceramics, and are resistant to high temperatures and corrosion. Taking advantage of the heat resistance and corrosion resistance of AIN ceramics, it can be used to make high-temperature corrosion-resistant parts such as crucibles, Al evaporation dishes, and semiconductor electrostatic chucks.

3. Functional materials

Aluminum nitride can be used to manufacture high-frequency and high-power devices that can be used at high temperatures or in scenarios where certain radiation exists, such as high-power electronic devices, high-density solid-state memories, etc. As one of the third-generation semiconductor materials, aluminum nitride has excellent properties such as wide bandgap, high thermal conductivity, high resistivity, good ultraviolet transmittance, and high breakdown field strength. AlN has a bandgap width of 6.2 eV and strong polarization. It is used in machinery, microelectronics, optics, surface acoustic wave device (SAW) manufacturing, high-frequency broadband communications and other fields, such as aluminum nitride piezoelectric ceramics and Film, etc. In addition, high-purity AlN ceramics are transparent and have excellent optical properties. Combined with their electrical properties, they can be used to make functional devices such as infrared deflectors and sensors.

4. Inert heat-resistant materials

As a heat-resistant material, AlN can be used as crucibles, protective tubes, pouring molds, etc. Aluminum nitride can still have stable performance in a non-oxidizing atmosphere at 2000°C. It is an excellent high-temperature refractory material and has strong resistance to molten metal erosion.

5. Heat exchange components

Aluminum nitride ceramics have high thermal conductivity, low thermal expansion coefficient, excellent thermal conductivity efficiency and thermal shock resistance. They can be used as ideal heat shock resistance and heat exchange materials. For example, aluminum nitride ceramics can be used as heat exchanger materials for marine gas turbines and Heat-resistant components of internal combustion engines. Due to the excellent thermal conductivity of aluminum nitride material, the heat transfer capacity of the heat exchanger is effectively improved..

Enquiry

Enquiry