With the continuous development and advancement of electronic devices, high power density and high temperature have become one of the important challenges faced by modern electronic systems. Thermal management is a key factor in maintaining the reliability and performance stability of electronic devices. In this regard, this article will explore the thermal management capabilities of ceramic circuit substrates, introduce their applications in high-temperature environments, and discuss related technological advances and solutions.

Thermal conductivity of ceramic circuit substrates:

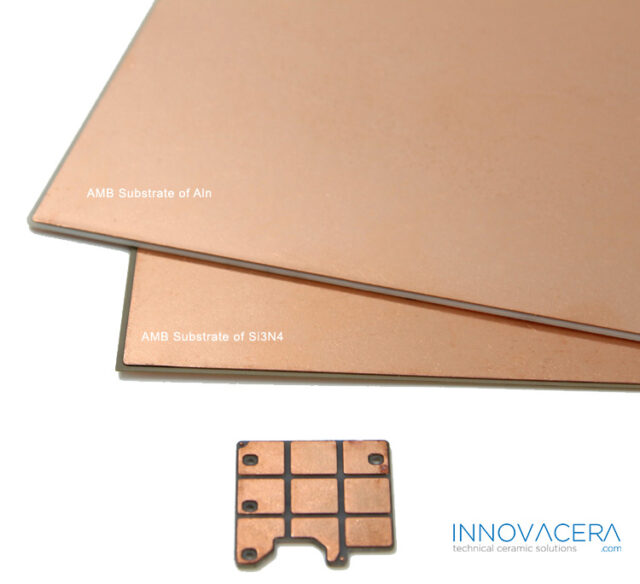

Ceramic materials have good thermal conductivity. In comparison, traditional organic substrate materials have low thermal conductivity. Common ceramic circuit substrate materials, such as aluminum nitride (AlN) and silicon nitride (Si3N4), have high thermal conductivity, respectively 170-200 W/(m·K) and 80-140 W/(m·K ). This allows the ceramic circuit board to dissipate heat more effectively, improving thermal management capabilities. (INNOVACERA provides a variety of high-quality ceramic substrate materials).

Thermal transfer and thermal design:

In high power density applications, thermal transfer and thermal design are critical. The thermal conductivity properties of ceramic circuit substrates provide designers with greater flexibility and possibilities. Through reasonable heat dissipation design, such as adding heat sinks or thermal vias, the thermal management capabilities of ceramic circuit substrates can be effectively improved, heat can be quickly transferred to the surrounding environment, and the temperature of electronic components can be reduced.

Application in high-temperature environments:

Ceramic circuit substrates have excellent performance in high-temperature environments. Its high melting point and excellent thermal stability enable it to withstand high-temperature operations and maintain a low coefficient of thermal expansion. This makes ceramic circuit substrates ideal for many applications in high temperature environments, such as aerospace, energy, automotive electronics and power electronics. In these applications, ceramic circuit boards provide stable operation and provide excellent thermal management capabilities to ensure system reliability and performance.

Technology progress and solutions:

In order to further improve the thermal management capabilities of ceramic circuit substrates, researchers continue to explore new technologies and solutions. Here are some common technology advances:

A. Heat transfer enhancement materials: By adding heat transfer enhancement materials, such as metal probes or nanopins, the thermal conductivity of the ceramic circuit substrate can be improved, thereby enhancing its thermal management capabilities.

B. Thermal interface materials: The selection and application of thermal interface materials is very important for optimizing thermal management. High thermal conductivity thermal interface materials can improve heat transfer efficiency, reduce thermal resistance, and enhance thermal management capabilities.

C. Simulation and simulation tools: The use of thermal simulation and simulation tools, such as finite element analysis (FEA) and computational fluid dynamics (CFD), can help designers evaluate and optimize the thermal management performance of ceramic circuit substrates and provide accurate thermal design solution.

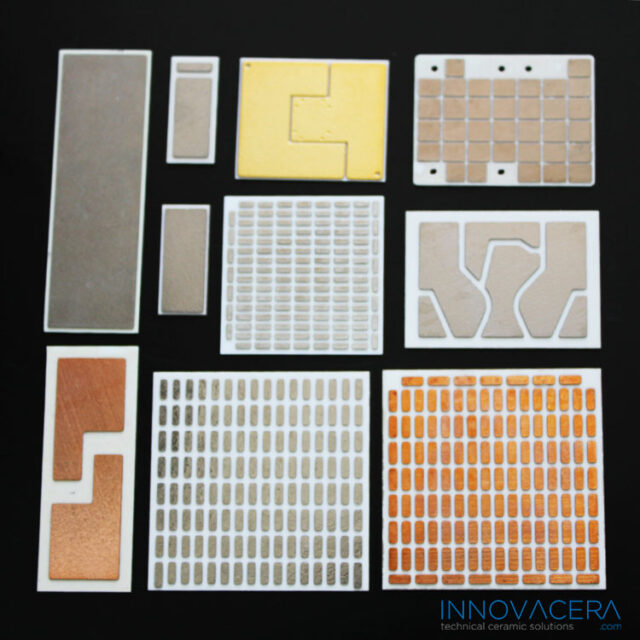

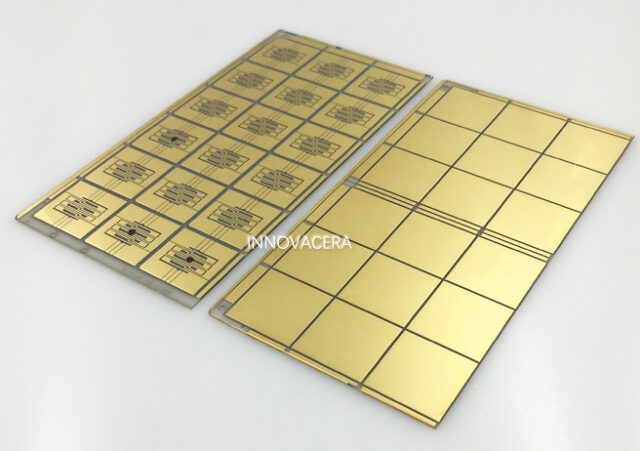

Conclusion: Ceramic circuit substrates show great potential in thermal management due to their excellent thermal conductivity and thermal stability. Through reasonable heat dissipation design and the application of thermal conductivity enhancement materials, the effective heat dissipation and heat dissipation capacity of ceramic circuit substrates can maintain the reliability and performance stability of electronic equipment. In high-temperature environments, the excellent performance of ceramic circuit substrates has become an ideal choice for many application fields. With the continuous advancement of technology and in-depth research, the thermal management capabilities of ceramic circuit substrates will be further improved, providing more reliable solutions for future high-performance density electronic systems. If you need ceramic substrates, ceramic heat sinks, etc. please feel free to contact us. INNOVACERA not only have a variety of ceramic materials, but also are good at various processing techniques, such as DBC, DPC, AMB.

Enquiry

Enquiry