Ceramic substrates are materials with unique thermal, mechanical, and electrical properties that make them ideal for demanding power electronics applications, typically used in Power Modules.

The most recent applications of power modules are for electric vehicles (EVs) and hybrid electric vehicles (HEVs), call for higher voltage and power from smaller circuits, requiring circuit materials capable of providing high voltage isolation with the efficient dissipation of heat from densely packed semiconductor devices such as IGBTs and MOSFETs. DBC and AMB Ceramic Substrates for Power Modules are connection components in which copper plates are bonded to each surfaces of a ceramic plate. These ceramic substrates are with a high thermal conductivity and a excellent electric conductivity of copper and a high insulation property. The high electrical conductivity of copper supports high current; the excellent dielectric properties of the ceramic substrates enable the high isolation needed for densely packed circuits in power modules. The CTE of ceramic substrates aligns more closely with that of the metal traces on the substrate and the components soldered to the substrate. That helps minimize stresses that can lead to component and solder joint fractures.

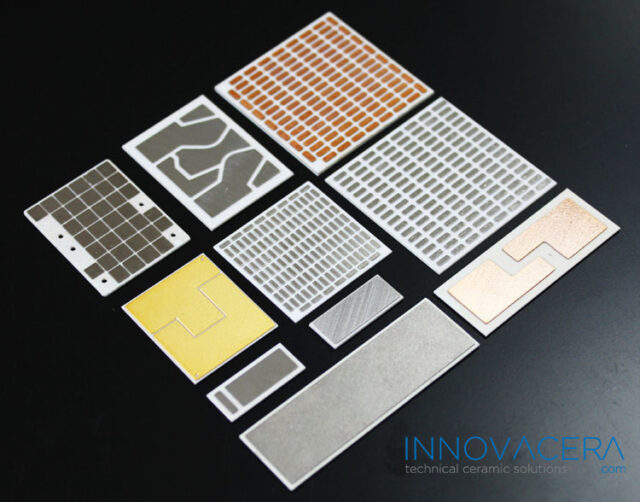

Ceramic substrates are implying copper layers on the ceramic plates, then etching with circuit pattern. The ceramic materials include Alumina, Aluminum Nitride, and Silicon Nitride. Copper is bonded to ceramic with different methods, including direct bond copper (DBC), direct plating copper (DPC) or active metal brazing (AMB) processes.

Materials comparison:

1. Aluminum Oxide Substrates

The most cost-effective material and good performance

Lower thermal conductivity

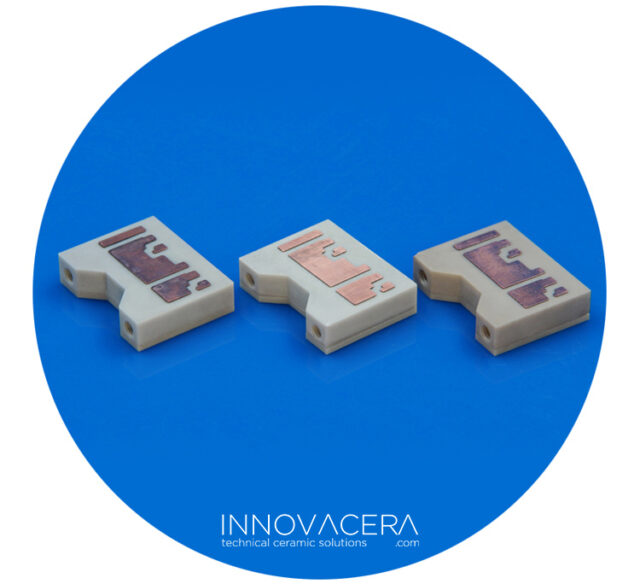

2. Aluminum Nitride Substrates

High thermal conductivity 170W/mK

CTE (Coefficient for Thermal Expansion) very close to silicon

High flexural strength

![]()

3. Silicon Nitride Substrates

Good flexural strength

Excellent fracture toughness

Good thermal conductivity

Enquiry

Enquiry