Aluminum Nitride combines high thermal conductivity with strong electrical resistance. They are an excellent solution for many electronic applications— allowing electrical systems to dissipate heat quickly for maximum efficiency.

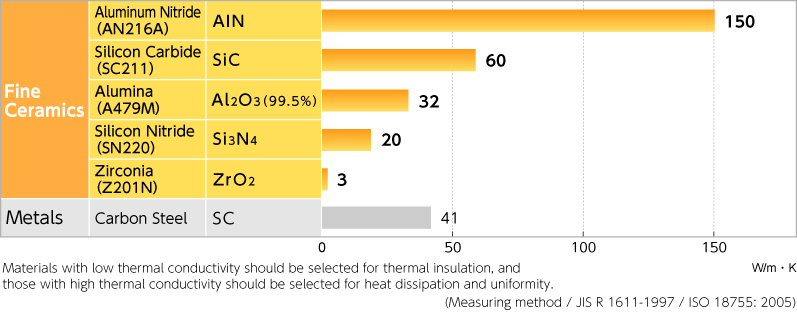

Thermal conductivity measures how well a material spreads heat within itself. Cooking pans have high thermal conductivity allowing evenly distributed heat to pass quickly into the food. On the other hand, insulative gloves are used to handle hot objects because their low thermal conductivity prevents heat from transmitting to sensitive hands. Technical ceramics are extraordinarily versatile, exhibiting a wide range of thermal conductivity.

Aluminum Nitride – High Thermal Conductivity Material

Ceramic thermal conductivity compare

Below is our Aluminum Nitride Ceramic material data sheet.

| Aluminium Nitride Material Properties | ||

| Properties | Value | |

| Bulk Density(g/cm3) | >=3.3 | |

| Water Absorption | 0.00 | |

| Flexural Strength(MPa) | >300 | |

| Vickers Hardness (Gpa) | 11.00 | |

| Modulus Of Elasticity (Gpa) | >200 | |

| Dielectric Constant(1MHz) | 8.80 | |

| Coefficient Linear Thermal Expansion | /℃,5℃/min, 20-300℃ | 4.6*10-6 |

| Thermal Conductivity | 30 degree Celsius | >=170 |

| Volume Resistivity(Ω.cm) | 20 degree Celsius | >1014 |

| 300 degree Celsius | 109 | |

| 500 degree Celsius | 107 | |

| Dielectric Strength(KV/mm) | 15-20 | |

| Remark: The value is just for review, different using conditions will have a little difference. | ||

Infineon has officially launched the new EasyDUAL™ CoolSiC™ power module, which uses aluminum nitride ceramics and has a half-bridge structure. It is suitable for 1200V high-power application scenarios, including solar uninterruptible power systems, auxiliary inverters, energy storage systems, and electric vehicle chargers. The CoolSiC module technology equipped with aluminum nitride ceramics can reduce the thermal resistance of the heat sink by up to 40%, which can increase the output power or reduce the operating temperature and improve the service life of the system.

We will work with you to find the optimal material for your application.

Enquiry

Enquiry