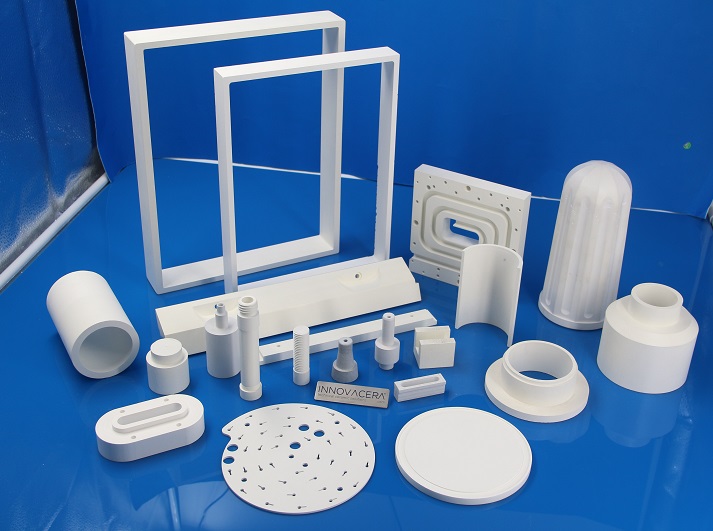

Nitride Boron can be used in the manufacture of crucibles for smelting semiconductors and metallurgical high-temperature vessels, amorphous strip nozzles, semiconductor heat dissipation insulation parts, high-temperature bearings, thermocouple bushing, and glass forming molds.

Usually produced Boron Nitride is a graphite-type structure, commonly known as white graphite. The other is diamond type. Similar to the principle of transforming graphite into diamond, graphite-type boron nitride can be transformed into diamond-type boron nitride under high temperature (1800℃) and high pressure (800Mpa).

The B-N bond length (156pm) of this boron nitride is similar to the C-C bond length (154pm) of a diamond, and the density is similar to the diamond. The hardness of this boron nitride is similar to diamond, but the heat resistance is better than diamond. It is a new type of superhard material with high-temperature resistance, which is used to make drill bits, grinding tools, and cutting tools.

What are the uses of Boron Nitride Ceramics

Boron Nitride Material Properties-SU0012

| Properties | Units | UHB | HB | BC | BMS | BMA | BSC | BMZ | BAN |

| Main Composition | BN>99.7% | BN>99% | BN>97.5% | BN+AL+SI | BN+ZR+AL | BN+SIC | BN+ZRO2 | BN+ALN | |

| Color | White | White | White | White Graphite |

White Graphite |

Greyish Green |

White Graphite |

Greyish Green |

|

| Density | g/cm3 | 1.6 | 2 | 2.0-2.1 | 2.2-2.3 | 2.25-2.35 | 2.4-2.5 | 2.8-2.9 | 2.8-2.9 |

| Three-Point Bending Strength |

MPA | 18 | 35 | 35.00 | 65 | 65 | 80.00 | 90 | 90.00 |

| Compressive Strength | MPA | 45 | 85 | 70.00 | 145 | 145 | 175.00 | 220 | 220.00 |

| Thermal Conductivity | W/m·k | 35 | 40 | 32.00 | 35 | 35 | 45.00 | 30 | 85.00 |

| Thermal Expansion Coefficient (20-1000℃) |

10-6/K | 1.5 | 1.8 | 1.60 | 2 | 2 | 2.80 | 3.5 | 2.80 |

| Max Using TemperatureIn Atmosphere In Inactive Gas In High Vacuum (Long Time) |

(℃) | 900 2100 1800 |

900 2100 1800 |

900 2100 1900 |

900 1750 1750 |

900 1750 1750 |

900 1800 1800 |

900 1800 1800 |

900 1750 1750 |

| Room Temperature Electric Resistivity |

Ω·cm | >1014 | >1014 | >1013 | >1013 | >1013 | >1012 | >1012 | >1013 |

| Typical Application: | Nitrides Sintering |

High Temperature Furance |

High Temperature Furance |

Powder Metallurgy |

Powder Metallurgy |

Powder Metallurgy |

Metal Casting |

Powder Metallurgy |

|

| High Temperature Electrical Furnace Components (High Temperature Insulator Sleeve Tube etc) |

√ | √ | √ | √ | √ | √ | √ | ||

| Metal Vaporize Crucible | √ | √ | √ | ||||||

| The Container Of Metal or Glass Melting |

√ | √ | √ | √ | √ | √ | √ | √ | |

| The Casting Mould Components Of The Precious Metal And Special Alloy. |

√ | √ | √ | ||||||

| High -Temperature Support Part |

√ | √ | √ | ||||||

| Nozzle And Transport Tube Of The Melting Metal |

√ | √ | √ | √ | √ | √ | √ | ||

| Nitrides Sintering | √ |

Remark: The value is just for review, different using conditions will have a little difference

Enquiry

Enquiry