High-Resistance Process-Grade Aluminum Nitride (AlN) is an ideal material for many semiconductor equipment and applications.

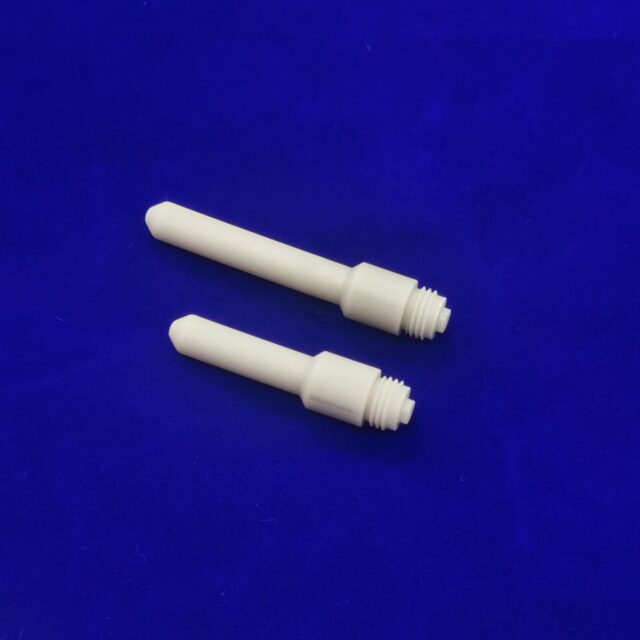

Innovacera designs Aluminum Nitrides (AlN) nozzles for precise gas flow rate and uniform control to evenly disperse gases into the etch process chamber. These components require high plasma resistance, dielectric strength, and strong corrosion resistance to the process gases and byproducts.

| Aluminum Nitride Material Properties | ||||

| Properties | INC-AN180 | INC-AN200 | INC-AN220 | |

| Color | Gray | Gray | Beige | |

| Main Content | 96%ALN | 96%ALN | 97%ALN | |

| Main Characteristics | High Thermal Conductivity, Excellent Plasma Resistance | |||

| Main Applications | Heat Dissipating Parts, Plasma Resistance Parts | |||

| Bulk Density | 3.30 | 3.30 | 3.28 | |

| Water Absorption | 0.00 | 0.00 | 0.00 | |

| Vickers Hardness(Load 500g) | 10.00 | 9.50 | 9.00 | |

| Flexural Strength | >=350 | >=325 | >=280 | |

| Compressive Strength | 2,500.00 | 2,500.00 | – | |

| Young’s Modulus of Elasticity | 320.00 | 320.00 | 320.00 | |

| Poisson’s Ratio | 0.24 | 0.24 | 0.24 | |

| Fracture Toughness | – | – | – | |

| Coefficient Linear Thermal Expansion | 40-400 degree Celsius | 4.80 | 4.60 | 4.50 |

| Thermal Conductivity | 20 degree Celsius | 180.00 | 200.00 | 220.00 |

| Specific Heat | 0.74 | 0.74 | 0.76 | |

| Thermal Shocking Resistance | – | – | – | |

| Volume Resistivity | 20 degree Celsius | >=10-14 | >=10-14 | >=10-13 |

| Dielectric Strength | >=15 | >=15 | >=15 | |

| Dielectric Constant | 1MHz | 9.00 | 8.80 | 8.60 |

| Loss Tangent | *10-4 | 5.00 | 5.00 | 6.00 |

| Remark: The value is just for review, different using conditions will have a little difference. | ||||

Kindly contact us for more details if you are working in this field

We’d love to discuss how our materials can offer you a solution.

Aluminum Nitrides (AlN) nozzles for Plasma Etch Equipment

Enquiry

Enquiry