When people refer to Beryllium Oxide, the first word that comes to their mind is “toxic”.

That’s true that the Beryllium Oxide powder is toxic, while after the manufacturing process the BeO ceramic is safe to be used. We’re going to talk about BeO:

First, the characteristics of beryllium oxide ceramics

Beryllium oxide has high thermal conductivity, high insulation, high melting point, high strength, low dielectric constant, low dielectric loss, high chemistry and stability, and good process adaptability.

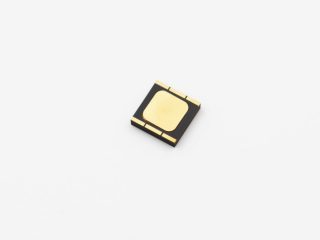

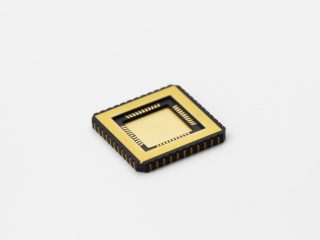

1. With superior thermal conductivity, BeO has been the mainstream ceramic material to produce high thermal conductivity components, especially in high-power semiconductor devices, integrated circuits, microwave electric vacuum devices, and nuclear reactors.

2. Its excellent electrical properties are also important. For beryllium oxide ceramics: As the dielectric loss tangent tanδ increases, ε does not change much. Therefore, BeO has a low dielectric loss.

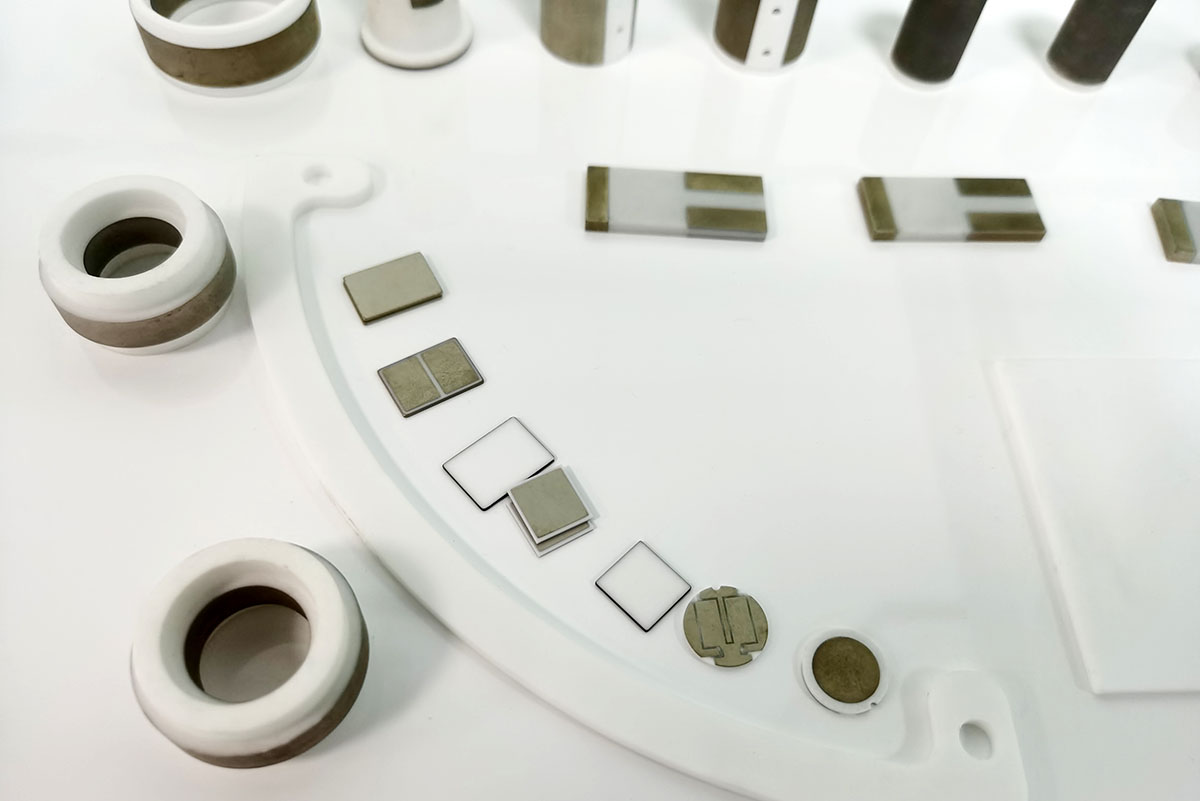

Second, due to its excellent characteristics, it is widely used in

1. High-power electronic devices and integrated circuits

2. Special metallurgy: Advanced refractory material

3. Vacuum electronics

4. Nuclear technology

5. Microelectronics and optoelectronic technology

So far the high thermal conductivity and low loss characteristics of Beryllium Oxide are hard to replace by other materials. While the protection measurement during the manufacturing process is strict and difficult, largely increases the cost, that’s why BeO is so expensive.

Enquiry

Enquiry