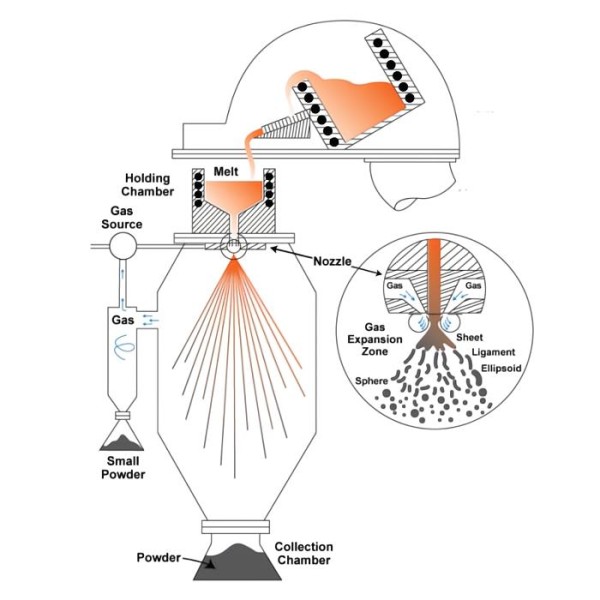

Boron Nitride nozzles are widely used in the processing of metal powder. Molten metal atomization is a process used to fabricate metal powder from a melt. In a typical atomizer, liquid metal is poured from a nozzle into a large chamber while being sprayed with high-pressure water, oil or gas. This causes the metal droplets to separate and condense into a powder that collects at the bottom. Atomization has become one of the most popular methods of powdering metals.

Atomization begins in a furnace where the metal is kept liquefied by electric heating elements. The metal falls into the spray chamber through a “nozzle” – this nozzle is designed to a high degree of perfection and specification. The nozzle is one of the most important parts of the atomization process – a damaged or clogged nozzle can cause the metal flow to stop or the flow to increase dramatically – both of which can disrupt the powdering process.

To prevent this from happening, the nozzle must be mechanically robust and offer no resistance to the flow of liquid metal. At the same time, the nozzle acts as an interface between the hot furnace at the top and the much cooler spray chamber below. Therefore, it needs to be made of a strong refractory material while also being resistant to high-temperature shocks.

Boron nitride has very low thermal expansion. Together with high thermal conductivity, this ensures that the material is very shock-resistant. It can easily withstand rapid changes in the temperature inside the atomizer. It will not crack or crack under thermal stress.

Under high vacuum, boron nitride can withstand high temperatures up to 1800 °C. A gas atmosphere can push the temperature further up to 2100 °C. This means boron nitride will remain solid during the melting of most metals.

It is also easily machinable, allowing us to machine small threads, holes and other finer details with high precision and tolerances. Nozzles made of boron nitride can be easily customized, allowing both constrained and free geometries.

Enquiry

Enquiry