Since the 1990s, the development of soft magnetic materials has gone through a glorious page: amorphous, nanocrystalline, metallic glass soft magnetic materials, magnetic powder cores, amorphous microcrystalline strips, and soft magnetic composite materials have paid more and more attention to the environment. Energy saving and emission reduction of countries all over the world bring hope. Soft magnetic materials are of great significance in miniaturization and high performance in the fields of automobiles, new energy, information, consumer electronics, and power electronics. If you’re looking forward to material for manufacturing magnetic alloy powder, please don’t hesitate to contact us for Boron Nitride nozzles.

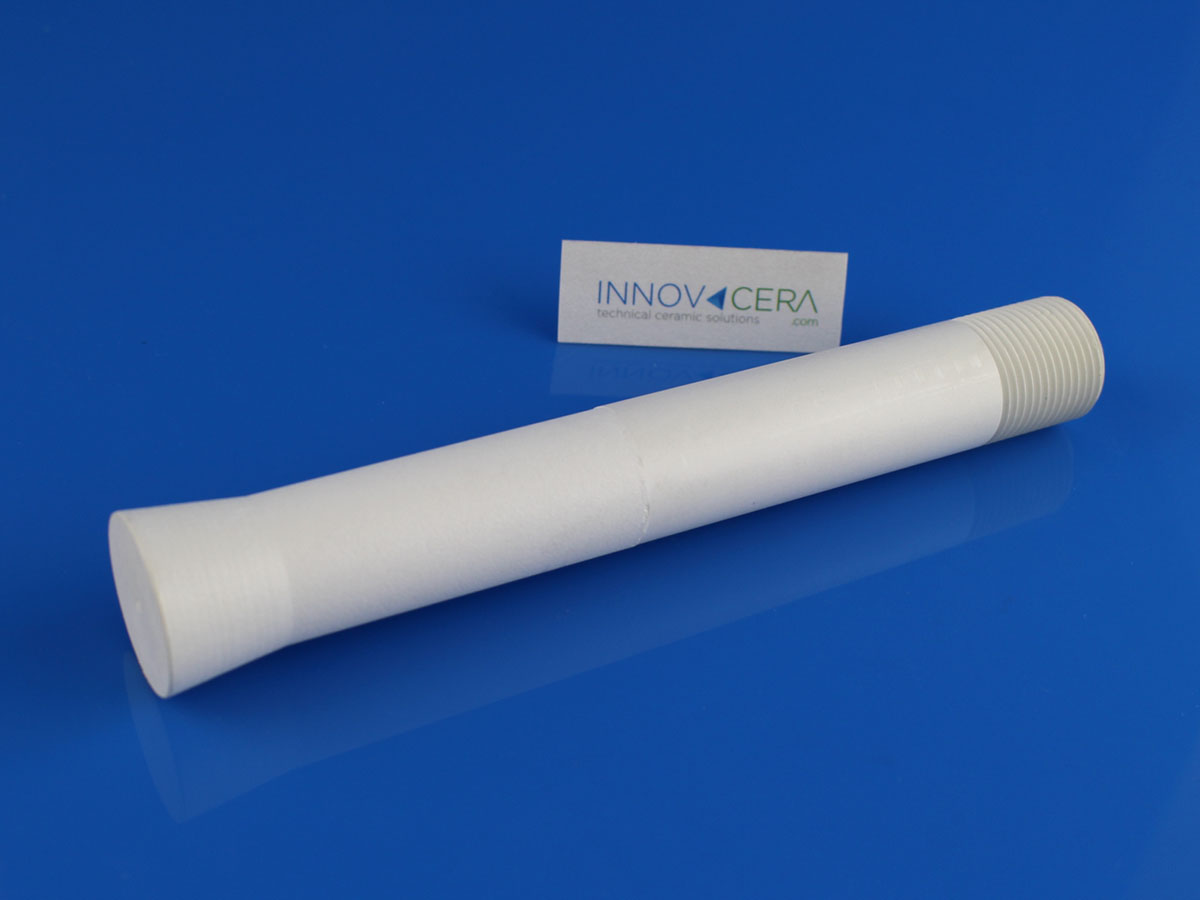

Boron Nitride nozzles are made by vacuum hot-pressed sintering. The material has features of fine structure, high density, erosion resistance, abrasion resistance, metal corrosion resistance and does not crack or deform during use. It is an excellent choice for the nozzle of soft magnetic material powder production.

Enquiry

Enquiry