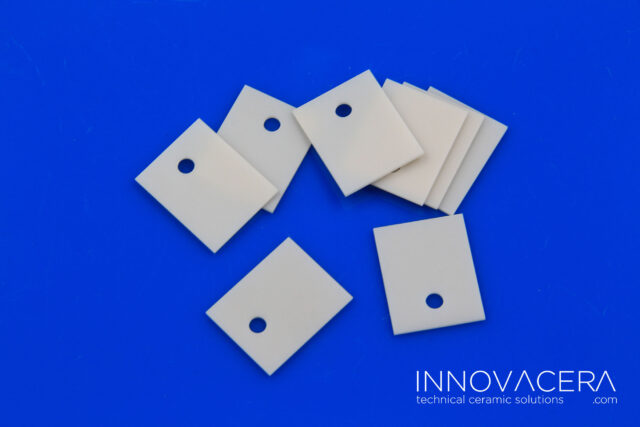

There are a lot of practical uses for ceramic in LEDs. First of all, they’re possibly the best material to use for heat sinks. This is because aluminum replaced copper as the cheaper alternative for heat sinks in LEDs. However, although it is relatively malleable and effective in conducting heat, it’s not that environmentally friendly to dispose of. This is where ceramic comes in! Ceramic is a very cost-productive material to use for heat sinks. This is because it is very easily available, can be printed out into heat sink shapes very easily and only needs the LED chip to be stuck directly onto it. This means using ceramic material for your LED’s heat sinks removes the need for PCB boards and thermal adhesives. Ceramic is a great alternative to previously used aluminum as they’re more environmentally friendly and contribute better to the overall heat dissipation of the light.

There are below benefits to use ceramic heat sinks:

Longer Lifespan: Having highly effective heat dissipation will prolong an LED’s life significantly. This is because LEDs are semiconductor devices and their internal components are made from materials that do not operate well under high temperatures. So the key is to find a way of shifting the heat away from the internal components to prolong the life of the LED.

Safer: Everybody knows a light running at a very high temperature is a safety risk. Especially LED’s at high temperatures. If your home has lights running at lower temperatures, there is much less risk to in one blowing or an accident happening.

Energy Efficient: An LED light with great heat-dissipating qualities will be more energy efficient. Although LED’s do run at lower temperatures than incandescent bulbs, they still have a lot of wasted energy as heat. If the light’s heat sinks are capable of removing the heat away from the internal components the LED light will have the capability of using less wattage with the same amount of lumens.

Below is different material thermal conductivity:

| Material | Thermal Conductivity(W/mK) |

| AlN | >200 |

| Aluminum | 235 |

| Al alloys | 166 -229 |

| Gold | 316 |

| Copper | 399 |

| Silver | 429 |

| Diamond | 900-2320 |

Although there are many good heat dissipation materials, the ceramic heat sinks is a great alternative and a very cost-productive material.

If you have more interesting, pls consult with us for ceramic heat dissipation solution.

Enquiry

Enquiry