With the development of intelligent devices in the direction of digitalization, miniaturization, low energy consumption, multifunctionalization, high reliability, etc., the closely related electronic packaging technology has also entered a period of ultra -high -speed development.

Commonly used electronic packaging substrate materials include three categories: organic packaging substrate, metal base composite substrate, and ceramic packaging substrate. With the evolution of intelligent devices, traditional substrate materials can no longer meet the current needs of the current development. Therefore, the base board materials are evolved from organic materials, metal materials, and evolution to ceramic materials.

As we all know, ceramic materials have many advantages compared to traditional substrate materials:

1. Low communication loss – The dielectric constant of the ceramic material itself makes the signal loss smaller.

2. High thermal conductivity – the heat on the chip is directly transmitted to the ceramic sheet. There is no need for insulating layer to achieve relatively better heat dissipation.

3. The more matched thermal expansion coefficient -the thermal expansion coefficient of ceramics and chips is close, and it will not cause too much deformation when the temperature difference drama changes causes the problem of line welding and internal stress.

4. High-temperature resistance – Ceramics can withstand a high and low temperature cycle with large fluctuations, and can even operate normally at a high temperature of 500-600 degrees.

5. High-electricity insulation – Ceramic material itself is an insulating material, which can withstand high breakdown voltage.

6. High chemical stability – Ceramic materials can be etched with acid, alkali, and organic solvents during processing.

7. High mechanical strength – The ceramic material itself has a good mechanical strength and good stability

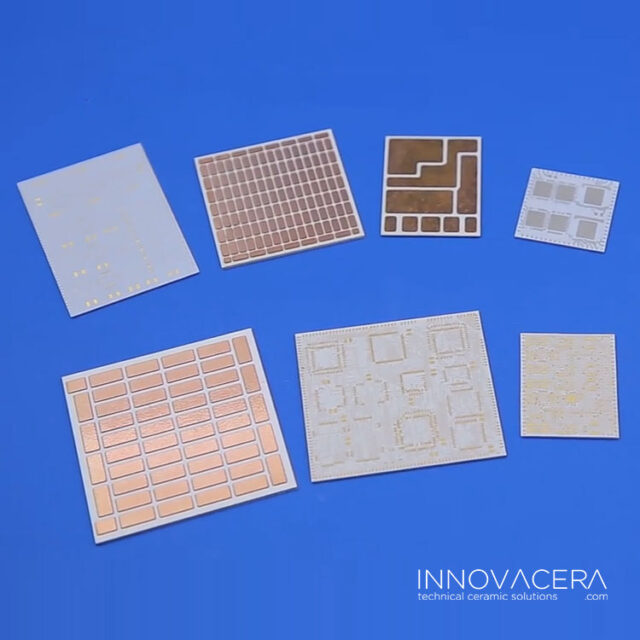

Therefore, ceramic materials have gradually developed into an ideal packaging substrate for new generation of integrated circuits and power electronic modules. The current commonly used ceramic substrate materials include Al2O3, AlN, and SI3N4. Ceramic metallized technology has also received extensive attention and rapid development.

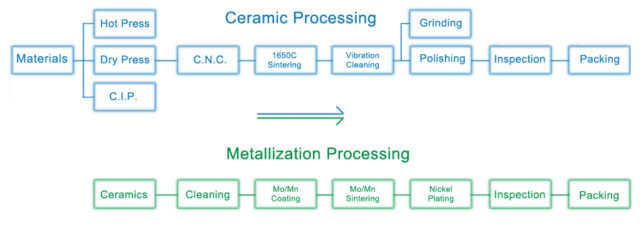

Finally, ceramic metallization process is as follows:

Enquiry

Enquiry