Aluminum nitride ceramics have excellent thermal conductivity, reliable electrical insulation, low dielectric constant and dielectric loss, non-toxic and matched with the coefficient of thermal expansion of silicon, a new generation of highly integrated semiconductor substrate and the ideal packaging material for electronic devices, but also can be used for heat exchangers, piezoelectric ceramics and thin films, thermally conductive filler.

AlN ceramics are used as copper-clad substrates, electronic packaging materials, ultra-high-temperature device packaging materials, high-power device platform materials, high-frequency device materials, thin-film materials for sensors, materials for optical electronics, coatings and functional enhancement materials.

Application:

1. Heat dissipation substrate and electronic device packaging

Ideal for packaging hybrid power switches and microwave vacuum tube housings, as well as substrates for large-scale integrated circuits.

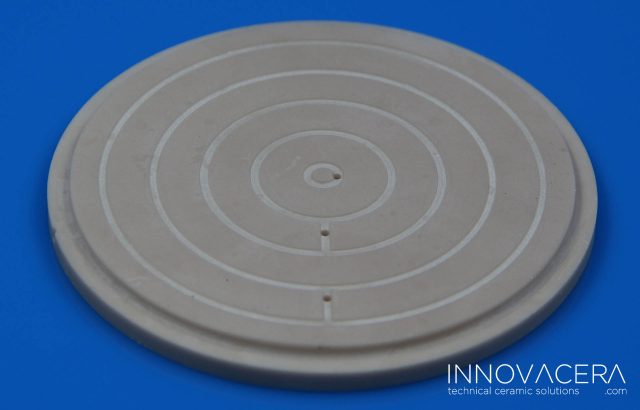

2. Structural Ceramics

AIN ceramics are heat and erosion resistant and can be used to make crucibles, Al evaporation dishes, semiconductor electrostatic chucks, and other high temperature corrosion resistant parts.

3. Functional Materials

Aluminum nitride can be used to make high-frequency, high-power devices that can be used at high temperatures or in the presence of radiation, such as high-power electronics and high-density solid-state memory.

High-purity AlN ceramics are transparent and have excellent optical properties, which, combined with their electrical properties, can be used to create functional devices such as infrared deflectors and sensors.

4. Inert heat-resistant materials

AlN as a heat-resistant material can be used as crucibles, protective tubes, casting molds and so on. Aluminum nitride can be in 2000 ℃ non-oxygenated atmosphere, still has a stable performance, is an excellent high-temperature refractory materials, resistance to molten metal erosion ability.

5. Heat exchanger parts

Aluminum nitride ceramics with high thermal conductivity, low coefficient of thermal expansion, excellent thermal conductivity and thermal shock resistance can be used as ideal heat-resistant impulse and heat exchanger materials, for example, aluminum nitride ceramics can be used as heat exchanger materials for marine gas turbines and heat-resistant parts for internal combustion engines.

6. Filler material

Aluminum nitride has excellent electrical insulation, high thermal conductivity, good dielectric properties, good compatibility with polymer materials, is an excellent additive for polymer materials for electronic products, can be used for TIM filler, FCCL thermal conductivity dielectric layer filler, widely used in electronic devices, heat transfer medium, and thus improve efficiency, such as the CPU and the heatsink to fill in the gap, the high-power transistor and silicon components and the substrate in contact with the slit place Thermally Conductive Fillers.

Enquiry

Enquiry