The most prominent feature of machinable ceramics is its good machinability. It can be turned, milled, planed, sawed, ground, cut, tapped, etc. using general-purpose metal processing equipment into a variety of parts with complex shapes, and can achieve a fairly high degree of machining accuracy. No special tools and equipment are required.

Machinable Glass Ceramic have excellent electrical insulation properties, high mechanical strength, resistance to rapid cooling and heating (widely used in welding fixtures, optical glass molding dies, etc.). Its corrosion resistance is also superior to ordinary ceramics, relative to PTFE, it is more resistant to corrosion, not aging, long service life so that it is used in various types of chemical equipment.

Machinable ceramics have high volume resistivity and high dielectric strength, making it an excellent electrical insulation material. It has excellent insulation and dimensional stability, and it is completely non-porous, non-absorbent, and does not outgas at 1000℃, so it can be applied in the vacuum field; good corrosion resistance, it can be used as heat-resistant parts in corrosive environments and parts in three-waste treatment devices; machinable ceramics have good thermal shock resistance, ultra-high vacuum stability, resistance to high and low temperatures, dimensional stability, and a specific gravity that is lighter than luminum, etc., which makes it It has become a universal material in the field of astronautics.

Machinable Glass Ceramic not only has the nature of ceramic materials, but also has the characteristics of metal materials, the combination of the two together, so that can be processed ceramics have many excellent features at the same time, but also has no ceramic materials, high toughness, general industrial ceramics because of the low strength, so in the application of structural materials has great limitations, and can be processed ceramics is not too big a concern, so in many cases, can be processed ceramics ceramics can be used in place of other industrial ceramics, and the use of the effect is not a big difference.

Machinable Glass Ceramic Material Properties – SU0005:

| Properties: | Units: | Remark: |

| Density | g/cm3 | 2.6 |

| Hardness | Mohs | 4~5 |

| Color | – | White |

| Coefficient of Thermal Expansion -50°C~200°C (Average value) |

°C | 7.2×10-7 |

| Thermal Conductivity | W/m.k (25°C) | 1.71 |

| Continuous Operating Temperature | °C | 800 |

| Flexural Strength | MPa | >108 |

| Compressive Strength | MPa | >508 |

| Impact Toughness | KJ/m2 | >2.56 |

| Elasticity Modulus | GPa | 65 |

| Dielectric Loss | (1~4)×10-3 | RT |

| Dielectric Constant | 6~7 | |

| Dielectric Strength (The thickness of sample: 1mm) |

KV/mm | >40 |

| Volume Resistivity | Ω.cm (25°C) | 1.08×1016 |

| 1.5×1012Ω.cm | °C | 200 |

| 1.1×109Ω.cm | °C | 500 |

| The Normal Temperature Outgassing Rate (Vacuum sophisticated 8 hrs) |

ml/s. cm2 | 8.8×10-9 |

| Helium Through Rate (After firing at 500°C, cooling to room temperature) |

ml/s | 1×10-10 |

| 5% HC1 (95°C, 24 hours) | mg/cm2 | 0.26 |

| 5% HF | mg/cm2 | 83 |

| 50% Na2CO3 | mg/cm2 | 0.012 |

| 5%NaOH | mg/cm2 | 0.85 |

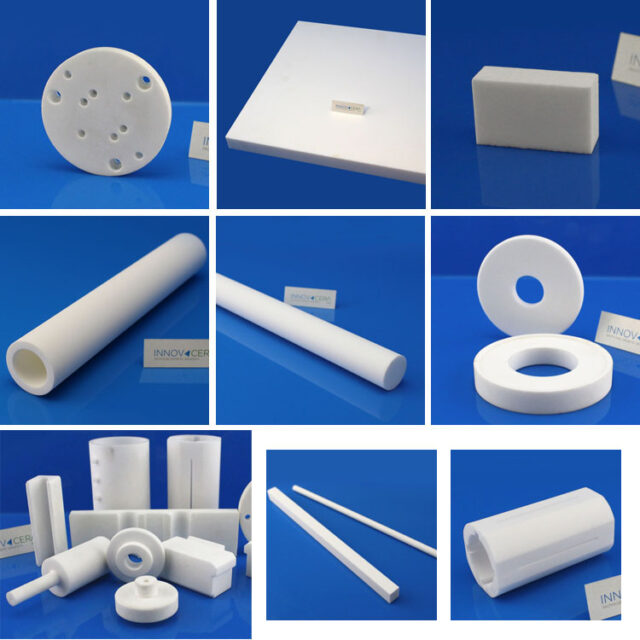

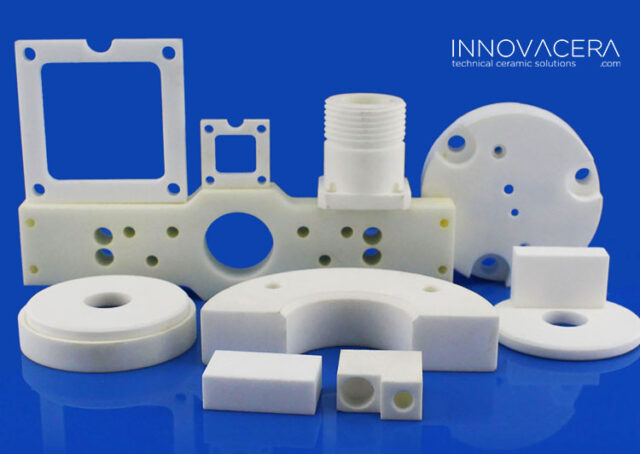

Machinable Glass Ceramic Related Products:

Machinable Glass Ceramic Structural Parts:

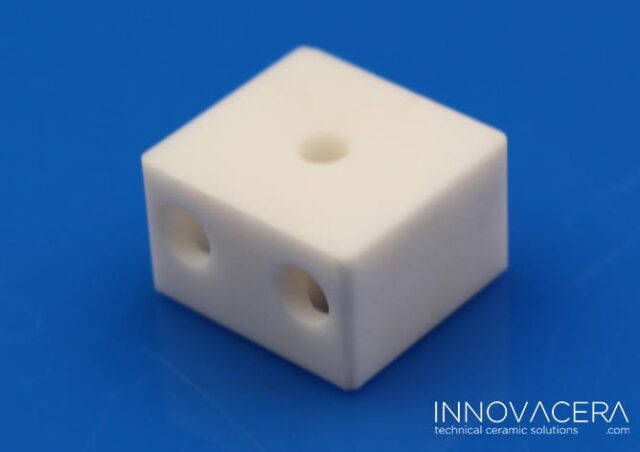

Machinable Glass Ceramic Ceramic Blocks:

Machinable Glass Ceramic Ceramic Pads:

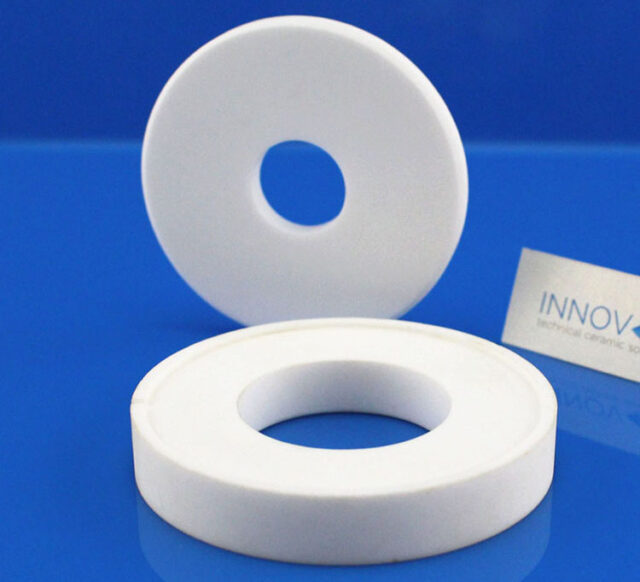

Machinable Glass Ceramic Rings:

Machinable Glass Ceramic Tubes:

Enquiry

Enquiry