Thermoelectric cooling is a new technology that has the potential to revolutionize the way things are kept cold, whether it is food, wine, beer or cigars. In fact, it is a completely different approach to refrigeration from standard compressors.

As we know that ceramic substrate plays a vital role in the thermoelectric cooler, the top and bottom of thermoelectric cooler(TEC) are ceramic substrate, which play the role of electrical insulation, heat conduction and support. And the biggest problems for the TEC is the heat dissipation.

To solve this problem it the top concern.

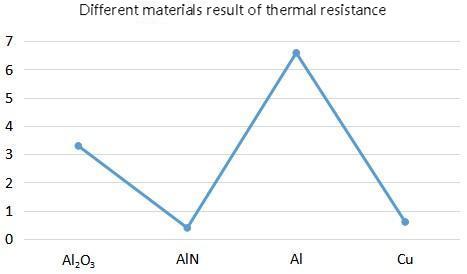

As different ceramic materials have different electronical and chemical properties. For example, the thermal conductivity of alumina is ≧24W/M.K, and the thermal conductivity of aluminum nitride is ≧170W/M.K. After the TEC is connected with the current, the temperature difference is generated due to the Parr effect, and the resistance encountered in the process of heat transfer inside the ceramic base is called the thermal conductivity resistance. The thermal resistance experiment shows that Al>Al2O3>Cu>AlN, aluminum nitride substrate has the lowest thermal resistance and the best thermal conductivity.

And the aluminum nitride substrate with thinner plate thickness has smaller thermal resistance.

The best choice is to use aluminum nitride substrate instead of alumina.

Enquiry

Enquiry