Magnesium Stabilized Zirconia Gas Atomizing Nozzles are mainly used in the powder metallurgy industry, ferrous and non-ferrous metal powder smelts, such as copper powders, nickel-based alloy powders, stainless steel powders, iron powders and other super alloy powders, etc.

According to different requirements for the qualities, INNOVACERA can supply the different stabilizers and grains combination.

INNOVACERA atomizing nozzles have higher density, excellent resistance to high temperature erosion, crushing of metal liquids and thermal shock stability.

INNOVACERA can provide various shapes and sizes atomizing nozzles and also individually customized according to customer’s demand.

At the same time, INNOVACERA also provide boron nitride containing composite boron nitride nozzles.

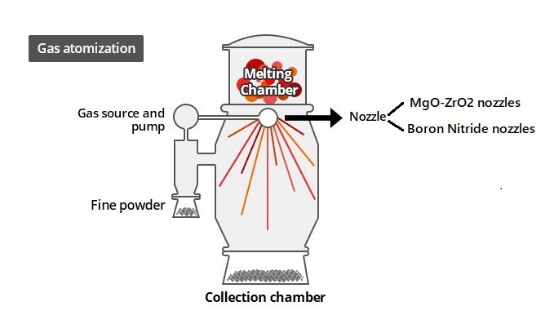

Gas atomization

Enquiry

Enquiry