The advocated global environmental preservation has brought the increasing stringent on emission regulations. How to reduce hydrocarbon (HC) emission at engine cold start is essential for an automotive, therefore, it’s necessary to control engine exhaust air to fuel (A/F) ratio and warm up the catalyst as quickly as possible. Oxygen sensors are widely used to control the A/F ratio at around the stoichiometric point, where three-way catalysts are most effective.

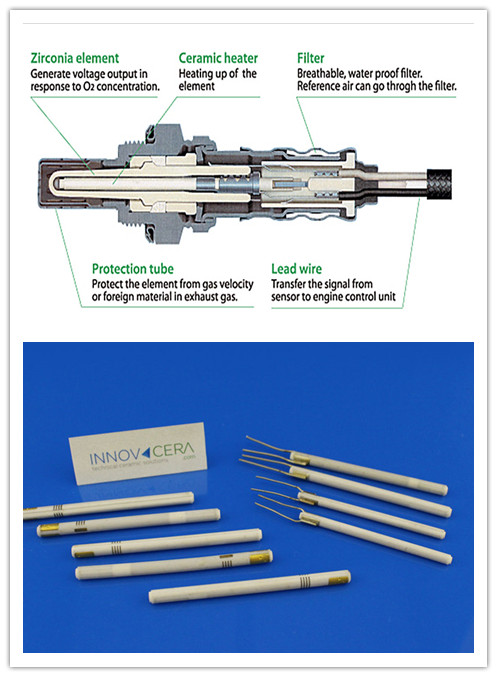

The traditional oxygen sensor is made of alumina and inserts into a zirconia ceramic tube and commonly takes some 20 seconds to activate.

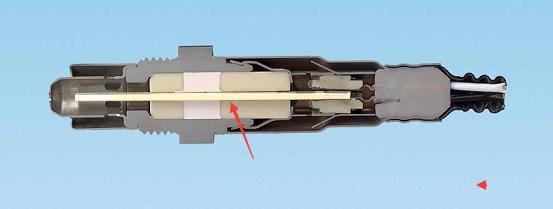

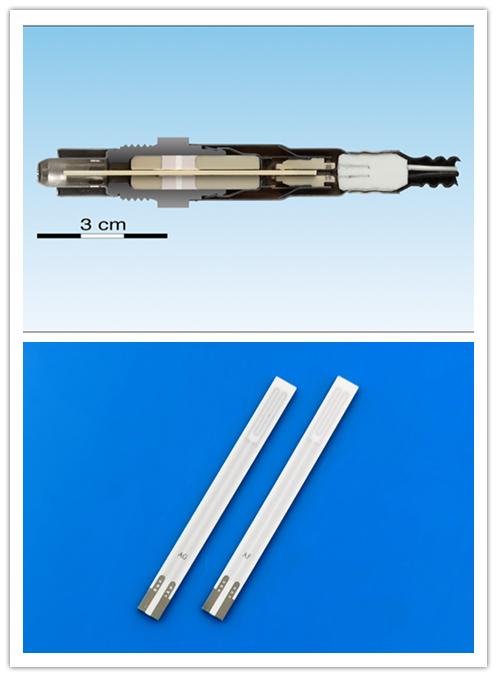

New laminated planar oxygen sensor combined alumina and zirconia together, heater element was embedded in the zirconia substrate of the sensor element adopting alumina for the heater substrate material, solve the problem of low thermal conductivity of zirconia while guarantee the good heating:

– High thermal conductivity and superior dielectric characteristic, by the direct joining of the alumina ceramic heater substrate and the sensor element zirconia electrolyte.

– Low heat stress at temperature rise, due to optimized heater design.

– Superior sensor protection from water droplets, and improved sensor response, due to optimized arrangement of intake holes in the sensor cover.

With these characteristics, the oxygen sensor can be activated in 10 seconds after a cold start.

Enquiry

Enquiry