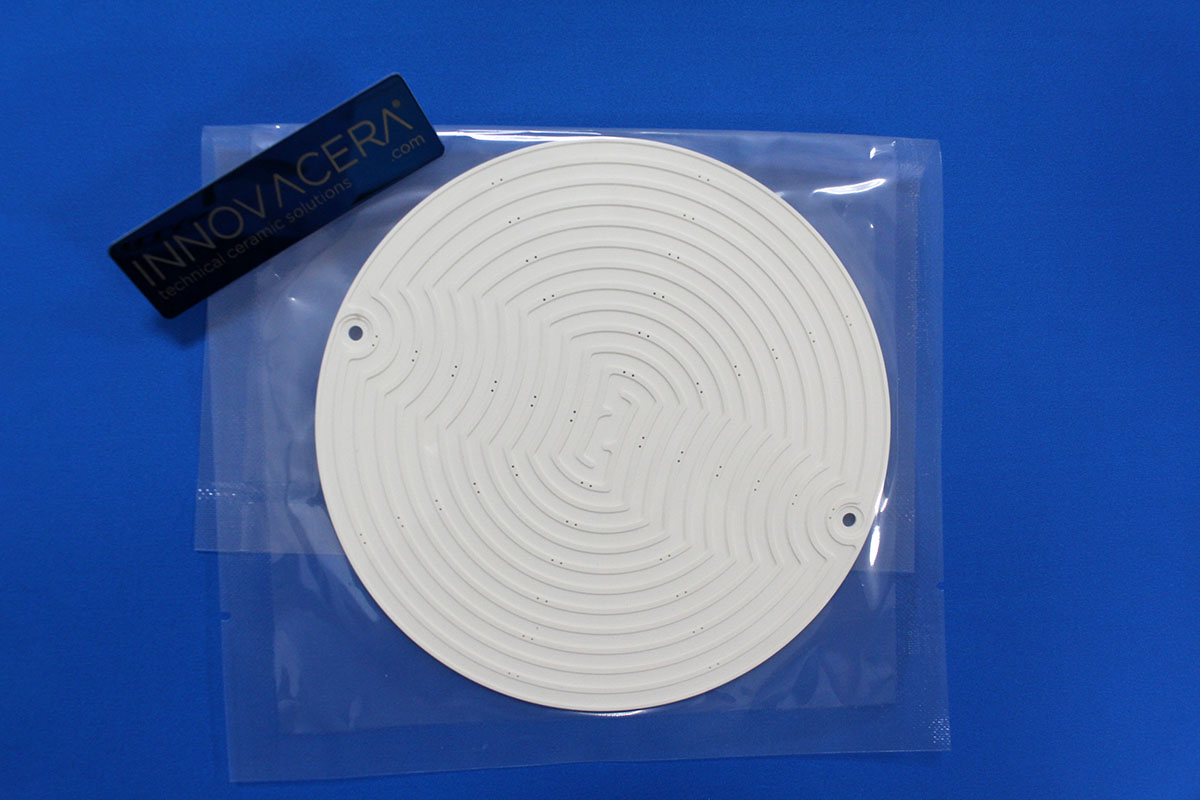

PBN as it is commonly referred to stands for Pyrolytic Boron Nitride and is produced by a process called CVD Chemical Vapour Deposition, with very good resistance to thermal shock. Our Pyrolytic Boron Nitride is always manufactured to our customer’s specific requirements on shape and size.

PBN is very attractive to many industry sectors, such as:

- Semiconductor

- Photovoltaic

- Coatings on Graphite

- Crystal Growth Crucibles

- OCVD (HB-LED) – Heater Components

- Hi-Temp Kiln & Furnace Components

Enquiry

Enquiry