Our customers come from all walks of life, and a large part of them come from laboratories in universities or research centers. For these researchers, our most suitable and standard product is the ceramic crucible. This word may be new to the general public. Still, crucibles are good friends of the lab and a loyal helper of researchers to do experiments. Clays originally made crucibles, and one of the earliest uses of platinum was also making crucibles. However, with the development of preparation technology, crucibles can now be composed of any material that can melt or change its contents.

Image by Skieze from Pixabay

What is a crucible?

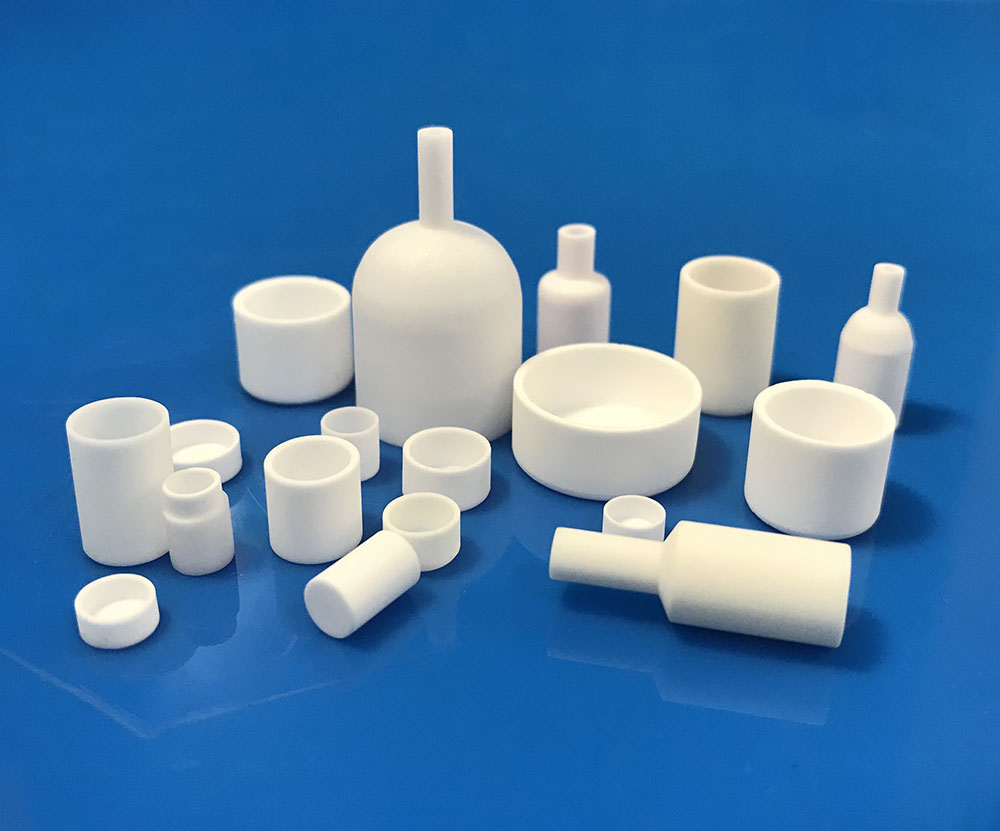

Crucibles are vessels made of extremely refractory materials such as clay, graphite, porcelain… Its role is to melt and refine metallic liquids, and also as a solid-liquid heating and reaction vessel. Crucibles belong to chemical instruments. When we heat solid by fire, we must use crucibles because they can withstand higher temperatures than glassware. There are mainly two ways of crucible usage. The first one is the burning of solid materials, and the second is the evaporation, concentration, or crystallization of solutions.

Different kinds of crucible

Corundum crucible, scientific name alumina crucible, people usually call crucibles with alumina content above 95% as corundum crucible. Corundum crucibles are reliable and resistant to melting, high temperature, acid and alkali, cold and extreme heat, and chemical corrosion. It is suitable for melting samples with some weakly alkaline substances such as anhydrous Na2CO3, but not ideal for using Na2O2, NaOH, etc. Strongly alkaline substances and acidic substances are used as fluxes to melt samples.

Image by Brennan Emerson from Pixabay

Image by Valeryna from Pixabay

BN (Boron nitride) ceramics have excellent heat resistance, thermal stability, thermal conductivity, and high-temperature dielectric strength, making them ideal heat dissipation materials and high-temperature insulation materials. Because of its unique chemical stability, BN can resist the corrosion of most molten metals. Because of the high-temperature insulation characteristics, high thermal conductivity, and low thermal expansion properties mentioned above, it is most suitable as an austere environment in semiconductor manufacturing and other situations. BN crucible is commonly used for smelting metals and semiconductors. Under vacuum, it can bear a temperature of up to 1800 degrees and under gas protection at a temperature of up to 2100 degrees. It is generally protected with nitrogen or argon (atmosphere protection is to prevent the crucible from oxidation ).

Zirconia has a high melting point and reaches 2700 degrees. It is one of the best refractory materials in nature. Even if heated to 1900 degrees, it will not interact with molten aluminum, iron, nickel, platinum, and other metals, as well as silicates and acids. So crucibles made of zirconia materials can successfully smelt platinum group precious metals such as platinum, palladium, ruthenium, cesium, and their alloys.

Graphite crucible is a refractory crucible made of natural crystalline graphite and plastic refractory clay as a binder. It is mainly used for smelting special alloy steel, non-ferrous metals, and their alloys, and is used in combination with different types of clinker. It maintains the fundamental physical and chemical properties of natural inks. That is, it has excellent thermal conductivity and high-temperature resistance.

Enquiry

Enquiry