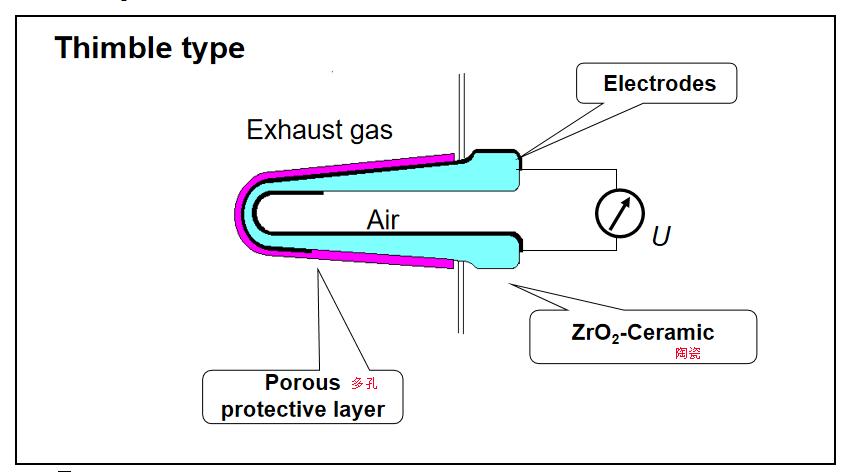

The oxygen sensor consists of an internal ceramic material called zirconia, with a porous platinum coating, and is protected by a metal casing. Its performance is based on changing the properties of ceramics at high temperatures, allowing oxygen to diffuse from the air.

It operates according to the difference in oxygen concentration between exhaust gas and outside air and generates a voltage of 50 mV to 900 mV.

The probe has a limitation: to start operation, it must be heated to approximately 300°C. In older probes, it is the exhaust gas itself that heats them, so you must wait a few minutes before putting the sensor into operation. Currently, there is a heating resistor next to the ceramic, even if the exhaust gas is in a low-temperature state, it can be heated for up to 10 seconds.

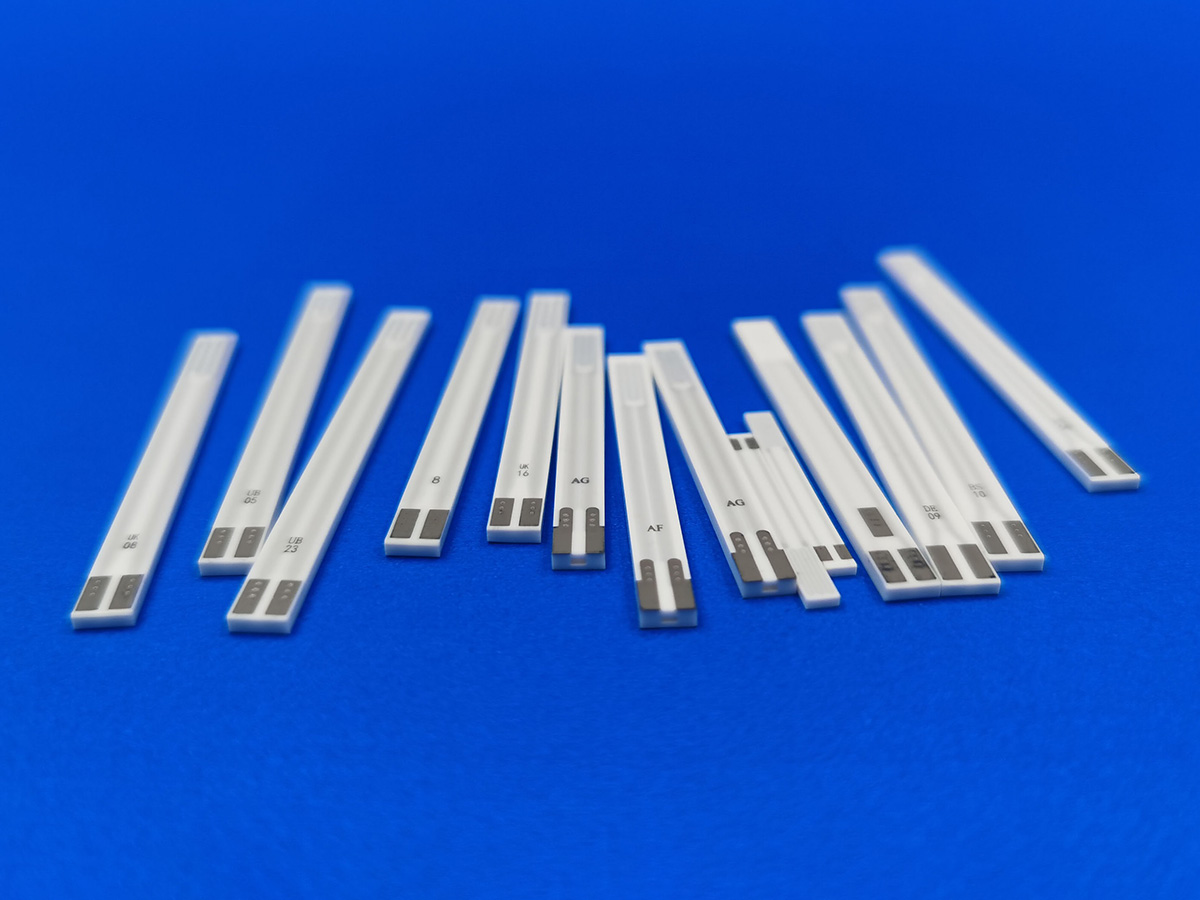

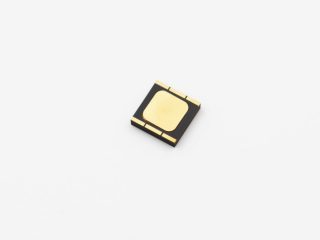

We have to make a thimble type and planar type of ceramic heater for the oxygen sensor.

Blow is the thimble type oxygen sensor structure drawing.

This is the structure drawing for the planar type

If you want to know more about oxygen sensor heaters, pls contact us at any time.

Enquiry

Enquiry