The oxygen sensor is a very important sensor. The function of the oxygen sensor is to sense the oxygen content of the exhaust gas discharged from the engine and give a signal to the engine computer in the form of voltage. The engine computer uses the signal of the oxygen sensor to control the fuel injection volume. If the oxygen sensor is damaged, it will have a problem of increased fuel consumption. If the oxygen sensor is loose, it is not acceptable, because it will leak. After the leak, the signal from the oxygen sensor to the computer may be inaccurate, affecting the engine’s power and fuel consumption, so if it is loose, it should be repaired as soon as possible.

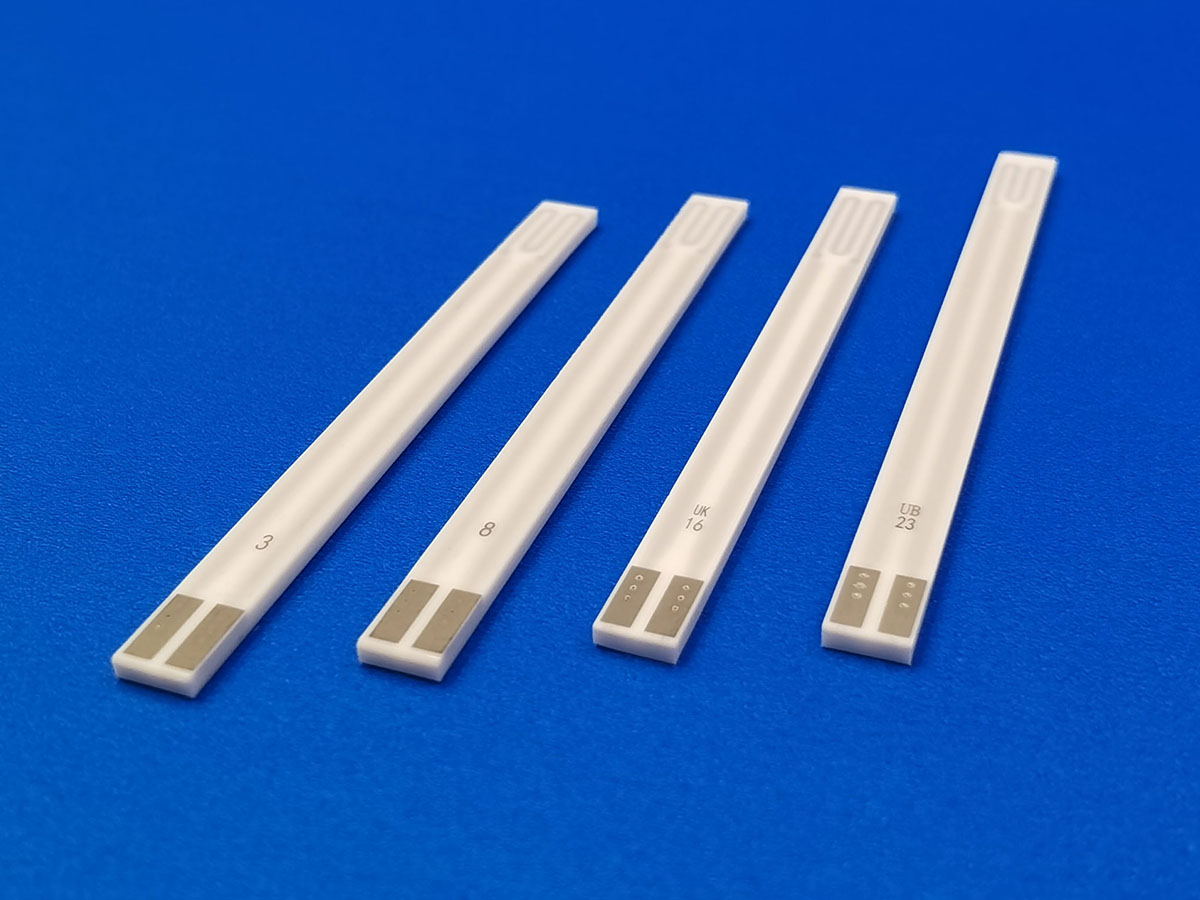

But do you know why the oxygen sensor will leak when assembling the ceramic heater chip?

There are two of the reasons:

One is the chip sealing is not doing well. Around the oxygen sensor piece, the power ring needs to be crushed to fill the gap. If there is no powder ring compaction, there will be a gap leakage problem.

The other is due to the high pressure of the pressing powdering ring, about 10 tons, and the oxygen sensor plate is not straight, which may break the oxygen sensor plate.

How to prevent the leak?

Our products will be 100% tested before leaving the factory, such as withstand voltage test, so there is no possibility of air leakage before leaving the factory.

Should you have more questions, please contact us at any time.

Enquiry

Enquiry