One of the popular application for MCH heater is the soldering iron, due to MCH heater provide fast heat up time and temperature stability, today let’s to know more about it.

Electric soldering iron is a common welding tool, widely used in electronic, electrical, communication and other fields. It is known for its easy operation and high welding efficiency. We will introduce the structure, working principle, use method, and how to choose the right electric soldering iron.

Working principle and structure of electric soldering iron

The operating principle of the electric soldering iron is based on heat conduction and electrothermal effect. It consists of a thermocouple, a heating element, a temperature control device and a handle. After the electric iron is energized, the heating element generates high temperature, and the thermocouple senses the temperature of the heating element and transmits the information to the temperature control device. The temperature control device will control the power supply of the heating element according to the set temperature, so that the electric soldering iron can maintain a stable operating temperature.

The electric soldering iron usually consists of a pen tip, a handle and a power cord. The pen tip is considered the most critical part, generally made of copper or steel, and tinned on the surface to improve thermal conductivity and service life. The handle is used for holding, effectively preventing heat conduction to the user’s hand, bringing a comfortable feeling. The power cord connects the soldering iron to the power supply to power the soldering iron to work.

Common types of electric soldering iron

The common types of electric iron on the market are: external heat type electric iron, internal heat type electric iron, constant temperature electric iron, tin absorbing electric iron and so on.

External heat type electric iron

The heating element is distributed on the outside of the cylindrical soldering iron head.Heating is slow but more secure.

Internal heat type electric iron

The heating element is inside the hollow iron head. It is fast heating and light weight.

Below is compare for two type of the soldering iron

| External heat type electric iron | Internal heat type electric iron |

| Using natural mica heating core, durable | High quality ceramic heating core, fast heating |

| Lead-free long life soldering iron head, high thermal efficiency | Lead-free long life soldering iron head, high thermal efficiency |

| The iron head wraps the heating core,Heat from inside. | The iron head wraps the heating core,Heat from inside. |

When choosing a soldering iron, you should take into account specific demand factors, such as heating speed, temperature control, and durability. It is also necessary to ensure that the products meet the safety requirements and have reliable quality to obtain a good use experience and welding effect.

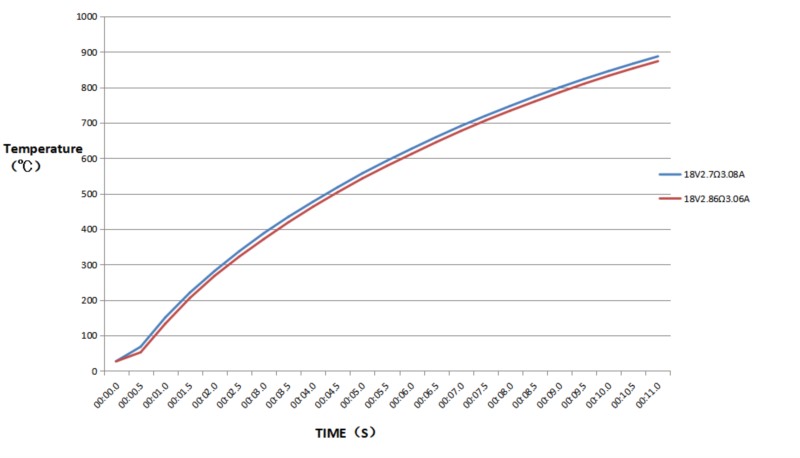

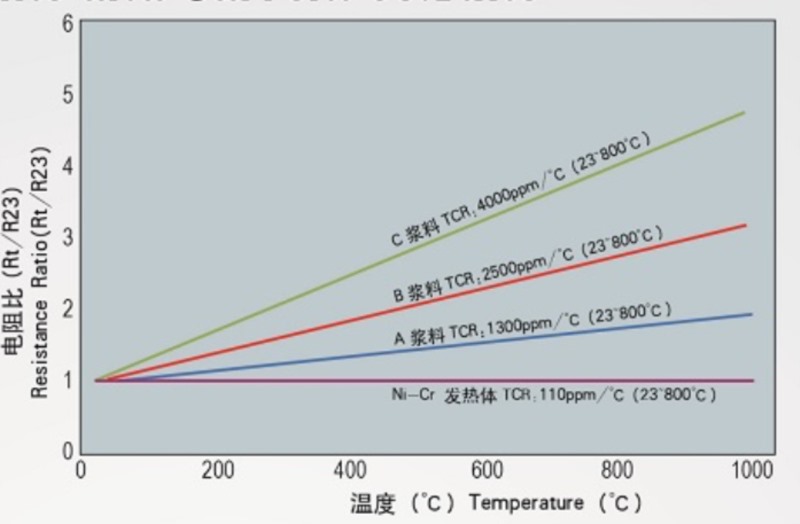

Blow is the Temperature curve and TCR value for MCH heater

We suggest to use MCH heater due to below benefits:

1.Fast Heat-Up Time: MCH heaters heat up quickly due to their low thermal mass, reducing the wait time before you can start soldering.

2.Temperature Stability: These heaters offer excellent temperature control and stability, maintaining consistent heat levels even during prolonged use.

3.Energy Efficiency: MCH heaters are highly efficient in converting electrical energy into heat, minimizing energy wastage and reducing operational costs.

4.Uniform Heating: The uniform heat distribution across the ceramic surface ensures that the soldering tip reaches and maintains the desired temperature evenly.

5.Compact Design: MCH heaters are compact and lightweight, contributing to the overall ergonomic design of modern soldering irons.

The properties of MCH heater

| Item | Unit | Alumina Heater |

| Max.Working temperature | °C | 1050 |

| Working temperature | °C | 850 |

| Thermal conductivity | W/m.k | 21 |

| Specific Heat | J/kg.k | 0.78X103 |

| Expansion | /°C(40-800°C) | 0.78X10-6 |

| Hardness (load 500g) | Gpa | 13.5 |

| Flexural | Mpa | 320 |

More application for MCH heater

E-cig, 3D printer, auto/motor oxygen sensor, smart bide/Instant water heating, small home appliances such as kettles, hair straighteners, curlers, hair dryer etc.

MCH heaters have revolutionized the performance of soldering irons by offering rapid heating, precise temperature control, and energy efficiency. These advanced heating elements enable soldering professionals and hobbyists alike to work with greater accuracy and effectiveness. As technology continues to evolve, we can expect further enhancements in soldering tools driven by innovations in heating technologies like MCH.

If you have any question about the MCH heater, welcome to contact us at sales@innovacera.com.

Enquiry

Enquiry