In a world where technological advancement knows no bounds, metallized ceramic substrates have emerged as a key player, enabling innovations in various industries. These versatile materials are gaining prominence in applications ranging from electronics to aerospace, thanks to their unique combination of electrical, thermal, and mechanical properties. Let’s explore the burgeoning landscape of metallized ceramic substrates and their ever-expanding applications.

Electronics Industry:

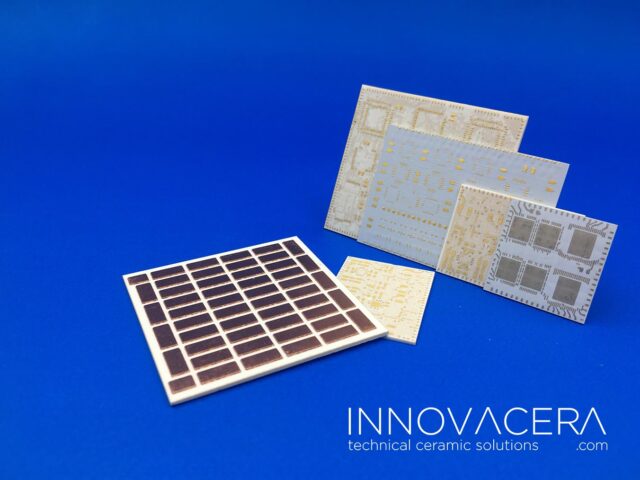

Metallized ceramic substrates have become indispensable in the electronics industry. These substrates provide a reliable foundation for the assembly of electronic components such as microchips and sensors. Their excellent electrical conductivity, thermal resistance, and ability to dissipate heat make them ideal for high-performance electronic devices.

One notable application is in power electronics, where metallized ceramic substrates are used in the manufacturing of power modules, inverters, and converters. These components play a crucial role in renewable energy systems, electric vehicles, and industrial machinery, contributing to energy efficiency and sustainability.

Aerospace:

The aerospace sectors are also tapping into the potential of metallized ceramic substrates. These substrates are essential in the development of radar systems, communication equipment. Their ability to withstand extreme temperatures and harsh environments ensures the reliability of critical components in aerospace applications.

Metallized ceramic substrates have found their way into satellite technology, enabling the miniaturization of components while maintaining exceptional performance. This has led to more cost-effective and efficient satellite systems, facilitating advancements in global communication and Earth observation.

Medical Devices:

Metallized ceramic substrates are making waves in the medical device industry. They are used in the production of high-frequency surgical equipment, medical imaging devices, and implantable devices. The biocompatibility and stability of these substrates are paramount in medical applications, ensuring patient safety and device longevity.

In the field of diagnostic equipment, metallized ceramic substrates play a pivotal role in the development of accurate and reliable diagnostic tools, such as X-ray machines and ultrasound transducers. These substrates enable precise signal transmission and reception, leading to improved healthcare outcomes.

Renewable Energy:

The transition to renewable energy sources relies heavily on metallized ceramic substrates. They are crucial in the manufacturing of photovoltaic cells and wind turbine components. The ability to efficiently dissipate heat ensures the longevity of renewable energy systems, reducing maintenance costs and increasing energy production.

Metallized ceramic substrates are also used in fuel cell technology, contributing to the development of clean and efficient energy solutions. Their corrosion resistance and electrical conductivity are key factors in enhancing the performance of fuel cells, making them a sustainable choice for power generation.

In conclusion, metallized ceramic substrates are becoming increasingly pivotal across a wide spectrum of industries, driving innovation and improving the efficiency and reliability of various technologies. As research and development efforts continue to expand the boundaries of what is possible, we can expect to see even more groundbreaking applications emerge, further cementing the role of metallized ceramic substrates in shaping our technological future.

Enquiry

Enquiry