The thermal conductivity of BeO ceramics is very high, which is comparable to that of some metal materials; it also has the advantages of high-temperature resistance, high-pressure resistance, high strength, and low dielectric loss, which meets the requirements of power devices for insulation performance. However, BeO powder is a highly toxic substance, which can cause serious harm to the human body and the environment. This fatal shortcoming greatly limits the production and application of BeO ceramic substrates in the industrial field

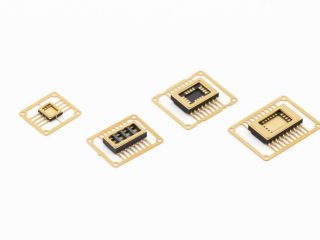

Beryllia Ceramic BeO Metallization

The most commonly used metallization method for BeO ceramics is the molybdenum-manganese method. The method is to apply a paste-like mixture of pure metal powder (Mo, Mn) and metal oxides on the ceramic surface, and then heat it at a high temperature in a furnace to form a metal layer. Adding 10%~25%Mn to Mo powder is to improve the combination of metal coating and ceramics.

However, the molybdenum-manganese method also has certain limitations on the metallization of BeO ceramics. The thermal conductivity of BeO ceramics can reach more than 300W/(m•K), but the thermal conductivity of molybdenum is only 146W/(m•K). It is not conducive to the high heat dissipation characteristics of BeO ceramics. In order to improve this drawback, the tungsten-manganese method was developed on the basis of the molybdenum-manganese method. The thermal conductivity of metal tungsten is higher than that of metal molybdenum, and the electrical resistivity of tungsten is also lower than that of metal molybdenum. Therefore, the tungsten-manganese method can not only improve the heat dissipation efficiency of the overall structure but also help to improve the electrical conductivity of the metallization layer.

Enquiry

Enquiry