Continuous casting is one of the most common metal manufacturing technologies. The liquid metal flows from a tundish into the mold, in which the strand shell is formed. The metal strand is then taken off continuously or intermittently, at a speed and solidification rate appropriate to the particular alloy.

Boron nitride with high chemical resistance against a vast majority of molten metals, combined with excellent thermal shock resistance makes it ideal for various molten metal contact applications. Additionally, due to the material’s strong high-temperature strength, moderate density, and big infiltration angle with molten steel, it exhibits good resistance to molten steel erosion and abrasion, extending the break ring’s service life significantly.

The ceramic break ring comes into contact with both the melt and the solidified alloy, and must satisfy correspondingly strict requirements:

- Chemical resistance to the solidified metal

- Good sliding properties

- High thermal shock resistance

- Defined thermal conductivity

- High wear resistance

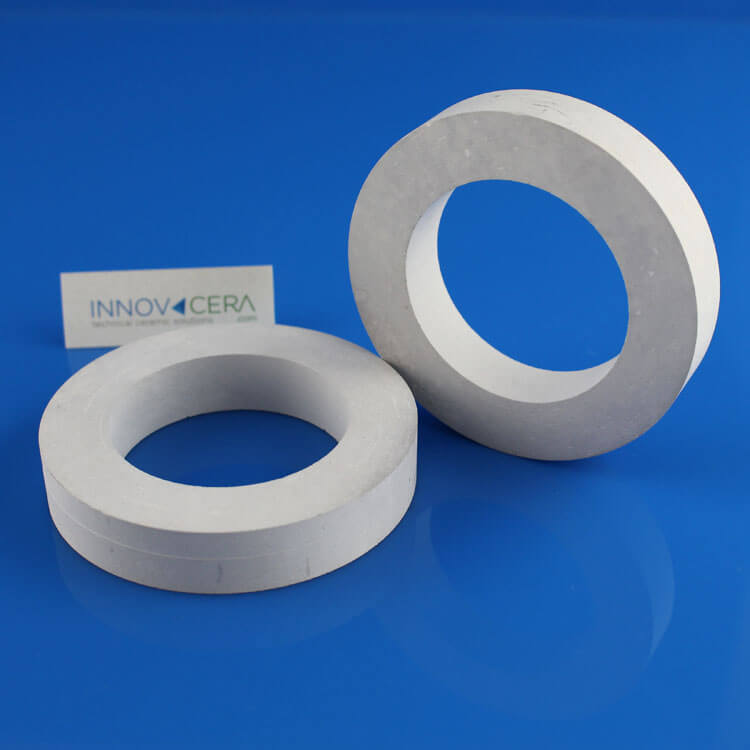

Boron Nitride Break Rings are extensively used in the metal casting Industry. Innovacera manufactures different boron nitride materials and boron nitride composites matched to different metal alloys, and it increases the lifetimes of the metals.

Boron Nitride Break RingsBoron nitride Ring

Enquiry

Enquiry