Outstanding features of Boron Nitride

- Good thermal expansion coefficient and excellent thermal shock resistance.

The thermal conductivity is 10 times that of quartz, which can reduce the risk of cracking due to rapid temperature changes. So there is no problem even after several cycles of 20~1200°C. - Boron nitride does not react with acids, alkalis, glass, and most metals, and its mechanical strength is low, only slightly higher than graphite, but there is no load softening phenomenon at high temperatures. It can be processed by general metal processing machines. It is suitable for melting and evaporating metal crucibles, utensils, liquid metal conveying pipes, and molds for casting steel.

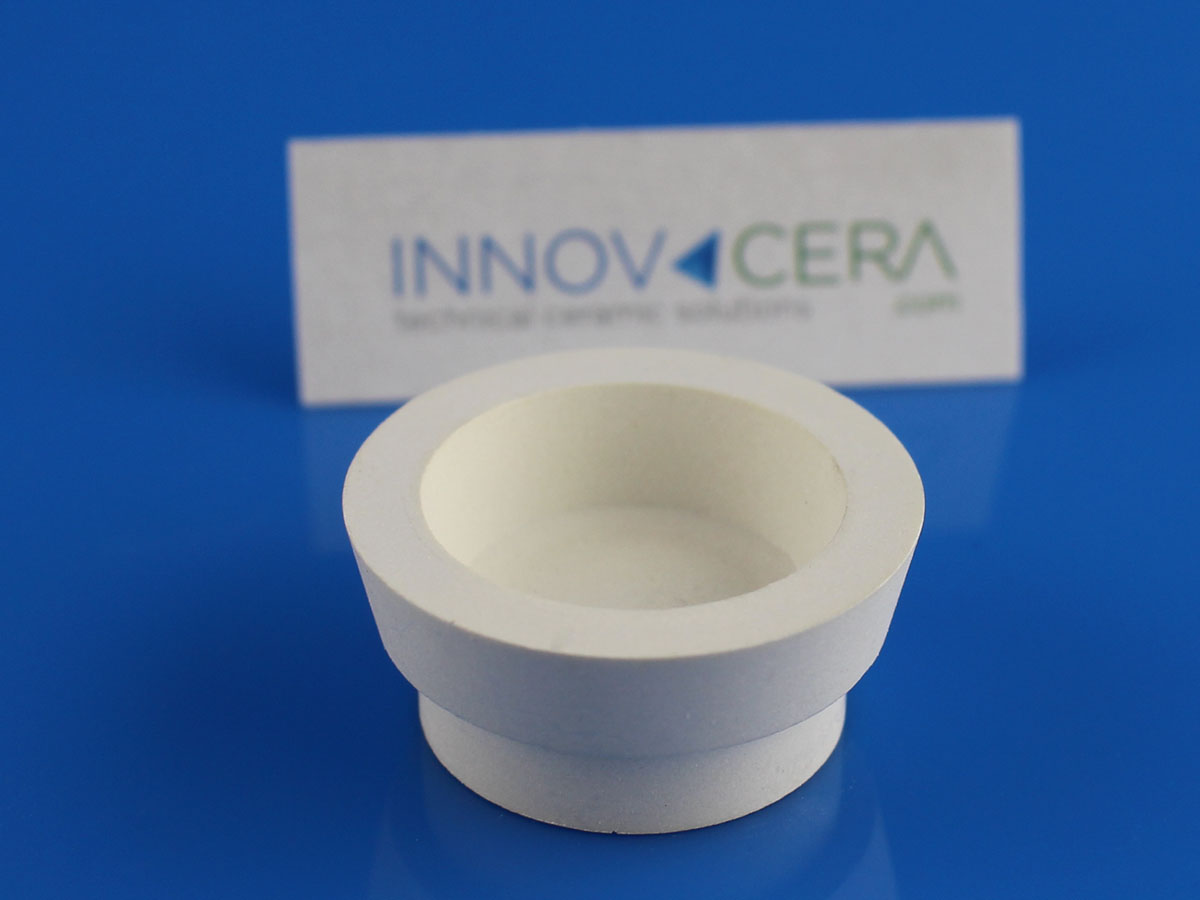

Classification of boron nitride crucible

- PBN crucible

The PBN crucible does not need to go through the traditional hot pressing sintering process and does not need to add any sintering agent, it has a high purity (above 99.99%), the operating temperature under vacuum is as high as 1800 degrees, and the operating temperature under atmosphere protection can reach up to 2100 degrees (Usually nitrogen or argon), it is mostly used in evaporation/molecular beam epitaxy (MBE)/GaAs crystal growth. - Sintered BN crucible

The sintered BN crucible is made of hexagonal boron nitride and sintering aids as raw materials, and is made by high-temperature sintering after molding.

It has good heat resistance, thermal stability, thermal conductivity, and high-temperature dielectric strength. So it can resist most of the erosion of the molten metal.

The sintered BN crucible contains a sintering aid (1~6wt%), the purity is not as high as that of the PBN crucible. It is suitable for making large-size crucibles. The maximum temperature used in inert gases such as argon or nitrogen is 2800°C; the stability in oxygen is poor and can only be used below 900°C.

Application of boron nitride crucible

- It is very suitable as a material used under strict environmental conditions such as semiconductor manufacturing processes. Group V semiconductors: gallium arsenide, gallium phosphide, and indium phosphide.

- It can also be used to make insulating materials or glass fixtures for various heaters, heating pipe sleeves, and high temperature and high frequency, High-pressure heat dissipation material.

Enquiry

Enquiry