MCH (Metal Ceramic Heater), is an advanced ceramic heating element of high-efficiency, environmentally friendly, and energy-saving. Nowadays, the ceramic heating element has been used in more and more applications to improve performance, such as household electric heating appliances, automobile gas oxygen sensors, medical equipment heaters, etc.

In recent years, E-cigarettes have gradually replaced traditional cigarettes, and the metal coils used in electronic cigarettes are also replaced by ceramic heating elements, mainly because:

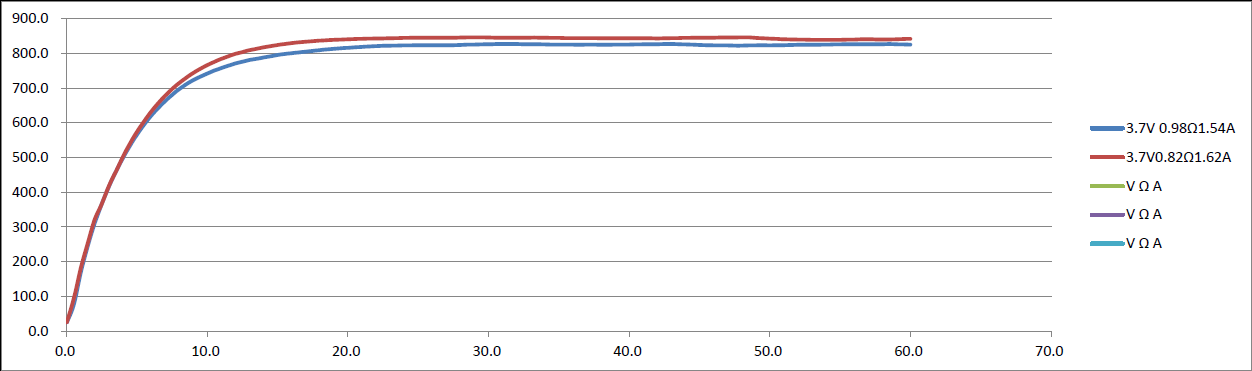

- The fast heating speed, it can be heated to above 200°C within 10 seconds at room temperature.

- The heat distribution is uniform, with excellent insulation, the ceramic surface is safe and uncharged.

- It does not produce harmful substances to the human body while heating and itself doesn’t contain harmful substances such as lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls, polybrominated diphenyl ethers, etc.

- Made of ceramic, acid, and alkali resistance, corrosion resistance.

- Long service life.

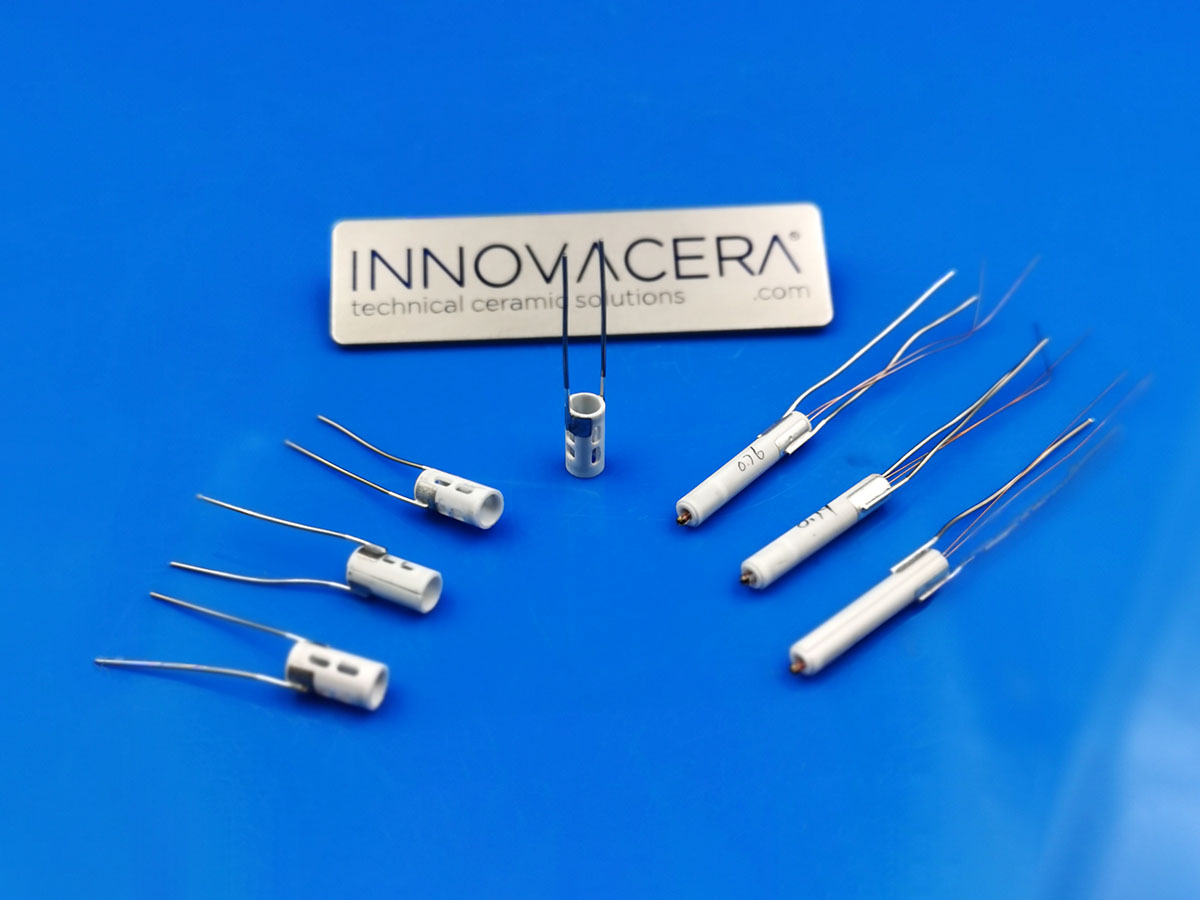

The plate, rod, and tubular ceramic heating elements produced by Innovacera can be widely used for different types of E-cigarettes, medical vaporizers, etc. In view of the increasingly strict regulations on E-cigarettes in various countries, the advantages of using ceramic heating elements are becoming more and more obvious.

Enquiry

Enquiry