Our special application area for high-temperature heaters is in heating systems that use solid fuels such as wood pellets as the energy source. The challenge here is to ignite the biomass in a very short time while retaining very low emission values. This can only be achieved with a sufficiently high ignition temperature.

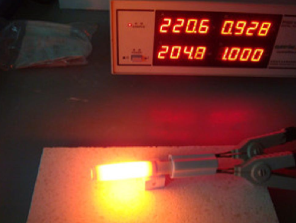

Our short surface ceramic igniters are perfectly suited for this purpose. The special geometry of the cylindrical ceramic heaters, in combination with an extremely high surface temperature of 1000°C, heats up the supply of air in the shortest possible time to an extremely high temperature. After a maximum of 90 seconds, the fuel is ignited with a fraction of the energy that is required for a hot air ignition blower. This works, of course, not only with pellets but also with wood chips, firewood, coal bricks or other solid fuels made of biomass.

the cylindrical ceramic heaters, in combination with an extremely high surface temperature of 1000°C, heats up the supply of air in the shortest possible time to an extremely high temperature. After a maximum of 90 seconds, the fuel is ignited with a fraction of the energy that is required for a hot air ignition blower. This works, of course, not only with pellets but also with wood chips, firewood, coal bricks or other solid fuels made of biomass.

Further product advantages:

-

- Ready assembled, easy-to-install systems

- Space-saving, noiseless and impervious to overheating (in case the blower fails)

- Extremely long-lasting and resilient

- Minimal energy consumption

- Completely electrically insulated

- No exposed electrical contacts

- No sensitive welding points

Not without reason, the high-temperature heating elements pellet igniter is the reliable standard ignition system for pellet heating systems in Europe-hundreds of satisfied customers speak for themselves.

Enquiry

Enquiry