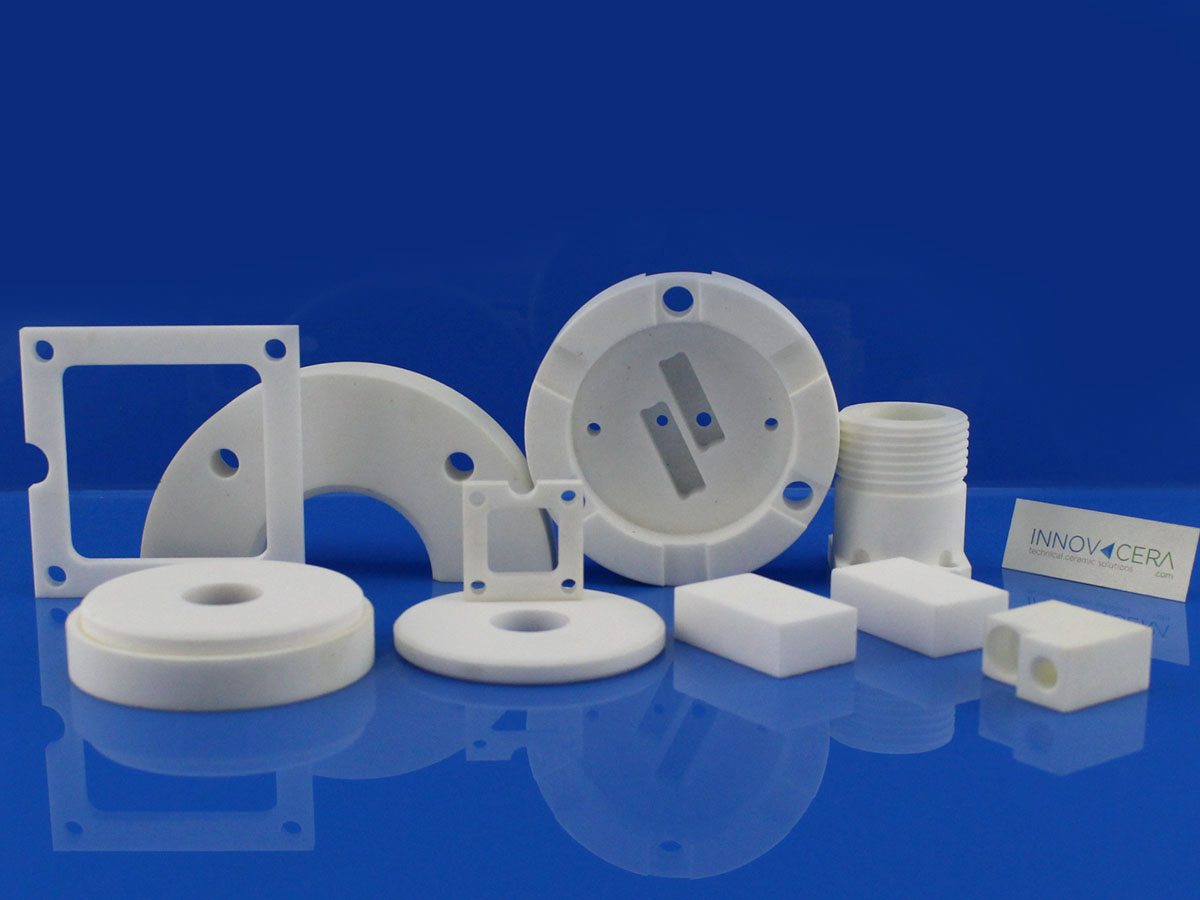

When you need the performance of a technical ceramic and your application requires a ready fabrication of a complicated shape, look to machinable glass ceramic. Machinable glass ceramic can be machined with ordinary carbide tools and requires no firing after machining. No costly delays, no post fabrication shrinkage and no costly tooling to meet specification.

Machinable glass ceramic withstands high temperature 900°C is non-porous/inert, and matches the thermal expansion of most metals. Applications of machinable glass ceramic includes

1. Ultra-High Vacuum Environments

Machinable glass ceramic is used as an insulator or coil support and for vacuum feed-through.In these applications, the conductive materials are supported by the MGC part and a compatible sealing glass is used to produce a vacuum-tight, hermetic seal.

2. Constant Vacuum Applications

Machinable glass ceramic is found in spacers, headers and windows for microwave tube devices and as sample holders in field ion microscopes.

3. Welding Nozzles

Welding equipment manufacturers are using MGC as a nozzle on the tips of oxyacetylene torches. The material’s non-wetting characteristic means molten particles won’t adhere to and decrease the effectiveness of the nozzle.

Enquiry

Enquiry