Machinable Glass Ceramic has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant.

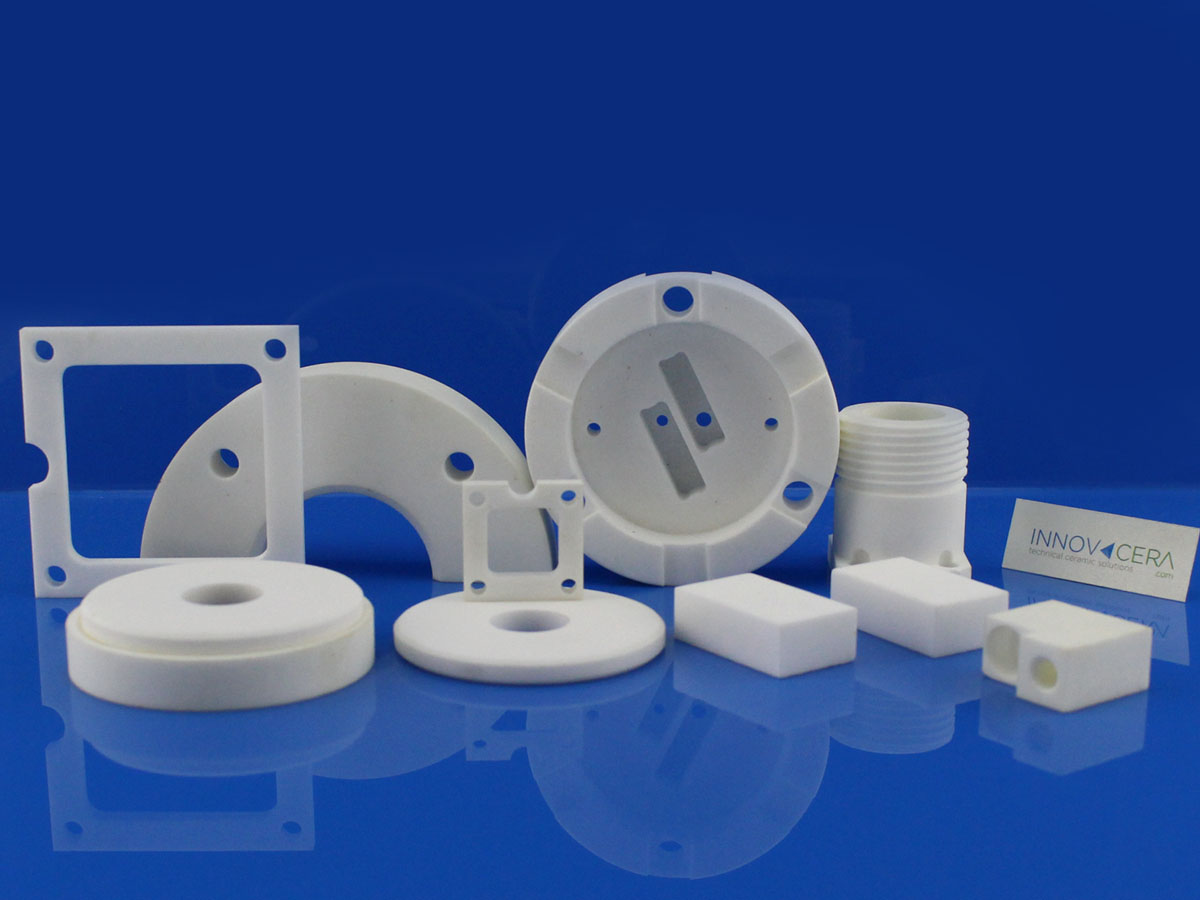

Machinable Glass Ceramic has a continuous use temperature of 800ºC and a peak temperature of 1000ºC. Its coefficient of thermal expansion readily matches most metals and sealing glasses. It has good machinability and can be lathed, milled, planed, ground, bored, incised and threaded. It also has the advantages of insulation, pore-free, high/low-temperature resistant, acid and alkali resistant and thermal impact resistant.

It is widely used for microwave high vacuum insulation, high precision magnetism-free skeleton for aeronautic and astronautic electrical devices, ultra-high voltage insulation for electric motors and structural parts at strong erosion environments. In terms of machinability, it can take place of aluminum oxide and boron nitride ceramics that are difficult to machine.

We can make rod with dimension Ф25mm~Ф160mm, up to 300mm long. And custom shape is ok for us.

Enquiry

Enquiry