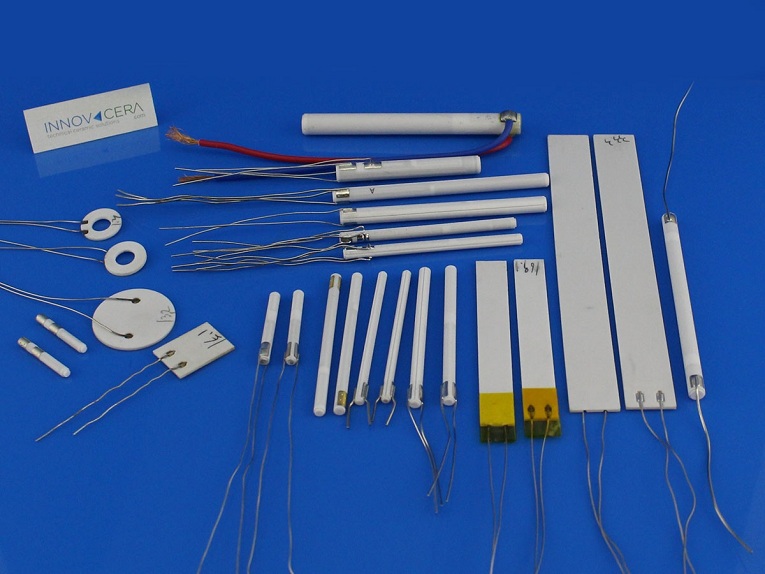

The MCH Heater is called Metal Ceramic Heater.

They are doing by HTCC. The short description is as below:

- Painting the high melting point metal(tungsten) paste on to the Al2O3 casting tape in coordinate to the circuit design, then another layer of sintering additives. After that, repeating the process to build multiple layers. Then, they are sintered together under 1600 °C hydrogen gas environment.

- Finally, nickel leads are brazed at 800 °C onto the metal end and put on with Teflon sleeve, which make it a MCH heating element.

- It is a new type of high efficient heating elements, which can save more than 20%-30% power effect compare to PTC ceramic heaters.

- Our alumina ceramic heaters have many excellent features that do not exist in the sheath heaters:

- High power density, excellent thermal efficiency

- Rapid heating, non-hotspot temperature distribution

- High temperature, small size, light weight

- Excellent insulation (the leakage current is < 0.5 mA under voltage 4500V/1S testing with no breakdown)

- High reliability, stable resistance, no electric noise Si Good chemical resistance

- Full compliance with EU RoHS (no lead, cadmium, mercury, hexavalent chromium, PCBS, and other harmful substances)

- No charge on surface and safe to touch.

The MCH is widely used in all kinds of applications nowadays, such as Fireplace, Pellet Boiler, Electric Iron, Boiler, Electric water heater, Medical machine, Dryer, electric heating splint, Vacuum flask, Electric cooker, capper, UTR cylinder condensation-proofer, Quick food heating, mini thermostatic bath for special crystal parts, automatic exhaust oxidation sensors, industrial equipment heater, and small heating appliance, etc.

Enquiry

Enquiry