Today we are going to introduce another popular application of the MCH heater used for oxygen senor, also called lambda sensor(O2 SENSOR).

LAMBDA SENSOR (O2 SENSOR)

The lambda sensor, also called lambda probe, measures the level of oxygen in exhaust gases and it’s placed on the engine exhaust. By analyzing the waveforms of operation of the lambda sensor in different modes of engine operation, functioning of the sensor itself can be assessed as well as the functioning of the engine management system on the whole. Sign of a malfunctioning lambda sensor is increased fuel consumption, vehicle dynamics reduction, loss of engine power, erratic idling or incorrect idle speed.

What is an oxygen sensor and how it works

Petrol engines require an exact air-fuel mixture proportion for a proper operation. The proportion, in which the fuel burns completely and effectively, is called a stoichiometric and is exactly 14.7:1. This means that one part of fuel must be mixed with 14.7 parts of air. In practice, this air-fuel proportion varies depending on the engine operation mode and the mixture formation. Thus the engine is uneconomic.

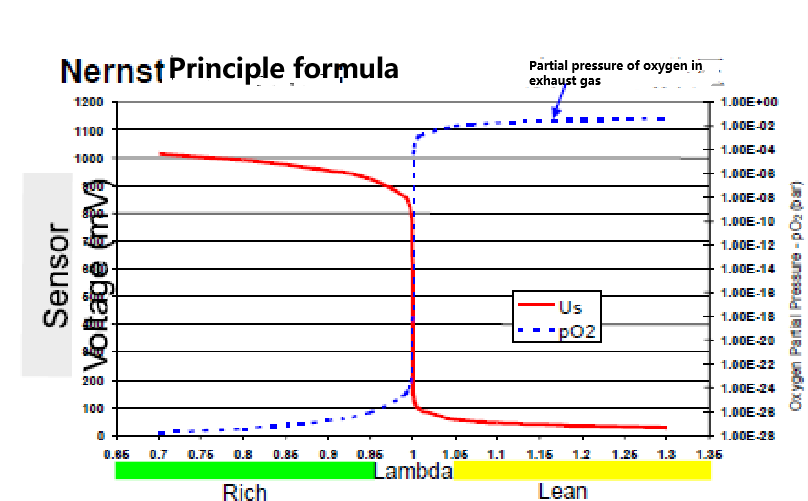

The excess air coefficient – L (lambda) characterizes how far is the actual fuel-air mixture from the stoichiometric (14.7:1). This mixture is considered optimal and in this case L = 1. If L < 1, we have a lack of air and the mixture is enriched. When L = 0.85 – 0.95 engine power is increased. If L > 1, there is an excess of air and the mixture is leaned. Engine power drops down when L = 1.05 – 1.3, but the economy rises. At L > 1.3 mixture becomes impossible to ignite and engine misfire occurs. Petrol engines reach their maximum power when a lack of air 5-15% (L = 0.85 – 0.95) is present, and a minimum fuel consumption is achieved with an excess air of 10 – 20% (L = 1.1 – 1.2).

Thereby when the engine is working, the proportion L is constantly varying in the range 0.9 – 1.1 and this is the lambda regulation operating range. When the engine warms up to its operating temperature and it’s not loaded (i.e. idling), keeping the equality L = 1 is essential in order the catalytic converter to completely fulfill its purpose and reduce the vehicle’s emissions to a minimum.

Oxygen sensor is mounted on the exhaust manifold so that exhaust gases can be on the streamline of its working surface. In essence the oxygen sensor is a galvanic current source, which changes its output voltage according to the temperature and the environment oxygen content. Depending on the exhaust gases oxygen concentration, a different output signal appears. Shape of this signal depends on the type of material the sensor is made from. Thus the oxygen sensor reports the onboard controller the amount of oxygen in exhaust gases. Clock edge of the signal between its “high” and “low” state, is negligible and can be ignored. The onboard controller receives signal from the oxygen sensor, compares it with a value stored in its memory and if the signal differs from the optimal for the current mode, it adjusts the fuel injection duration in both directions. Thus, by the implementation of a feedback and a correct operation mode, a maximum fuel economy and minimum harmful gases, is achieved.

Types of oxygen sensors

According to the substance used in their sensitive element, are:

Zirconium (zirconium oxide)

Titanium (titanium oxide)

Wideband

According to their design:

Single-wire lambda sensor

Two-wire lambda sensor

Three-wire lambda sensor

Four-wire lambda sensor

Single-wire lambda sensor was used in the early injection systems with a feedback (lambda regulation). It has only one terminal, which is the signal terminal. Sensor ground is its housing and it connects to the engine ground through the exhaust pipes.

Two-wire lambda sensor has a separate grounding cable. It was used in the early injection systems with a feedback (lambda regulation) also.

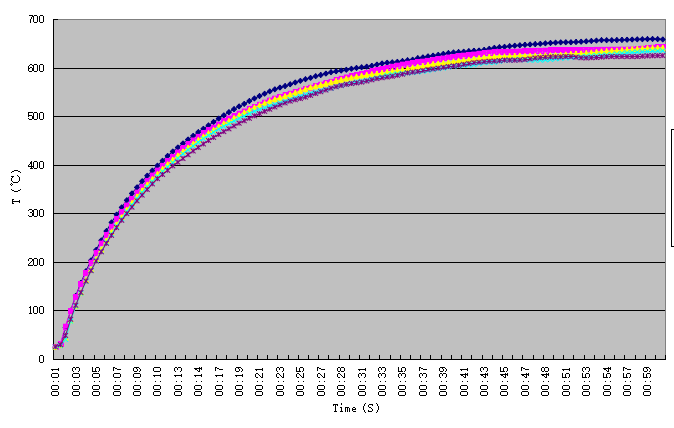

Disadvantage of the single-wire and the two-wire sensors is that their operating temperature range starts at 300 ºC. Sensor will not work and will not produce a signal until this temperature is reached. It was necessary for the sensor to be mounted as close to the engine cylinders as possible in order to heat and wrap from the hottest exhaust gases stream. Process of heating the sensor slows down the regulation process of the onboard controller because of the feedback. In addition, using the exhaust pipe as a signal ground requires sensor’s thread to be coated with a special electrically conductive paste, which increases the possibility of a bad contact in the feedback circuit.

In the three-wire lambda sensors, is a special heating element inside which is constantly turned on when the engine is working and thus it’s reducing the heating time of the sensor to the working temperature. This allows installation of the sensor on the exhaust manifold, near the catalytic converter. Disadvantage is the need of electrically conductive grease.

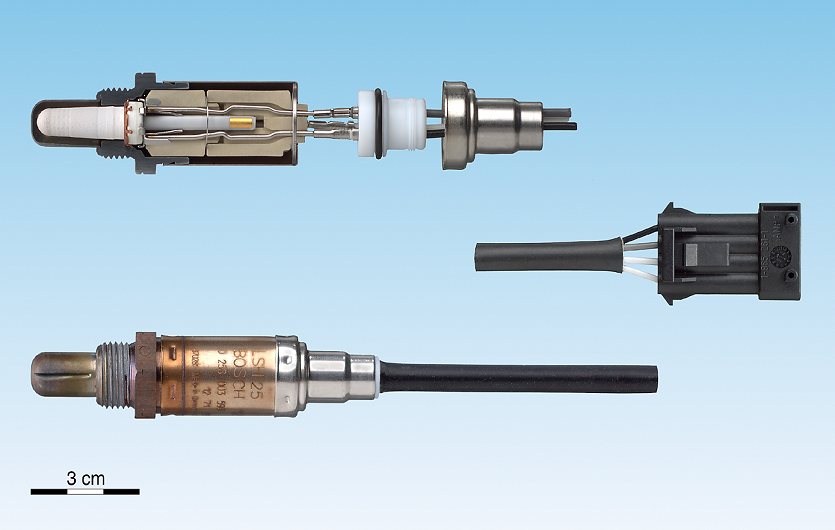

In the four-wire oxygen sensors – two of the terminals are the heater terminals and the other two, the signal terminals.

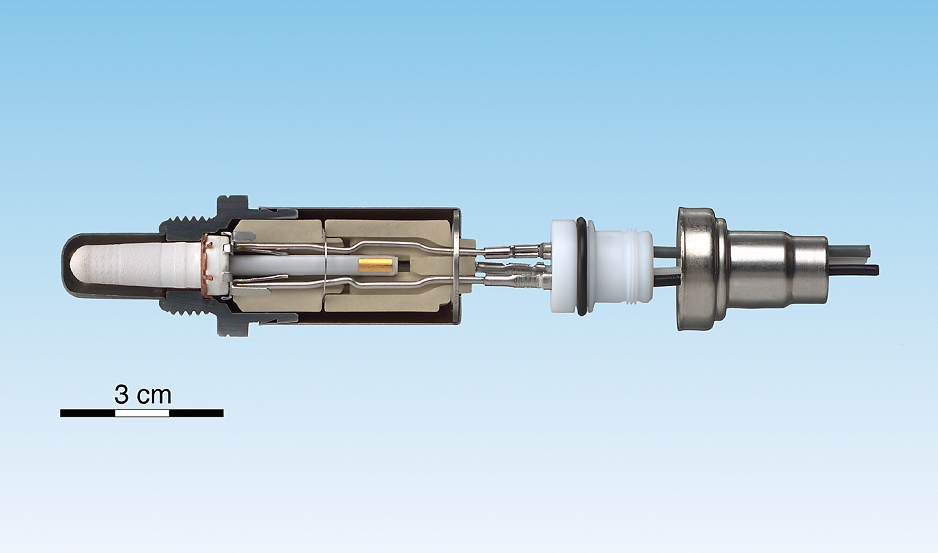

The structure of the ceramic heater in the oxygen sensor

The picture of MCH ceramic heater for oxygen sensor

Why use MCH heater?

-Quick Heating

-Temperature Stability

-Energy Efficiency:

-Uniform Heating

-Compact Design

The properties of MCH heater

| Item | Unit | Alumina Heater |

| Max.Working temperature | °C | 1050 |

| Working temperature | °C | 850 |

| Thermal conductivity | W/m.k | 21 |

| Specific Heat | J/kg.k | 0.78X103 |

| Expansion | /°C(40-800°C) | 0.78X10-6 |

| Hardness (load 500g) | Gpa | 13.5 |

| Flexural | Mpa | 320 |

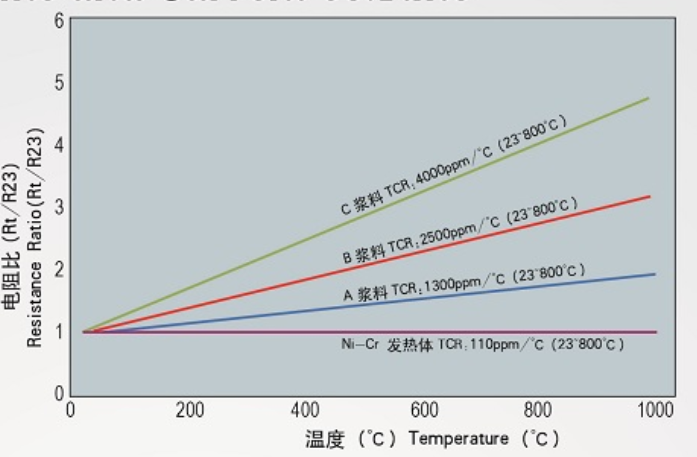

Blow is the Temperature curve and TCR value for MCH heater

More application for MCH heater

E-cig, 3D printer, soldering iron, smart bide/Instant water heating, new energy vehicle, small home appliances such as kettles, hair straighteners, curlers, hair dryer etc.

Conclusion

MCH heaters have great performance for the oxygen sensor by offering rapid heating, precise temperature control, and energy efficiency. These advanced heating elements enable oxygen sensor to work with greater accuracy and effectiveness.

If you have any question about the MCH heater, welcome to contact us at sales@innovacera.com.

Enquiry

Enquiry