In the contemporary industrial realm, pad printing technology finds extensive application across diverse surfaces, such as plastic, metal, glass, and ceramics. With the escalating demand for high-quality and durable prints, traditional pad printing rings frequently fail to fulfill the exacting printing requirements. Nevertheless, zirconia pad printing rings have emerged as the preeminent solution, presenting remarkable performance and durability.

What Are Zirconia Pad Printing Rings?

Zirconia represents an advanced ceramic material renowned for its extraordinary hardness, corrosion resistance, and wear resistance. Zirconia pad printing rings are fabricated using this robust material, thereby constituting essential components within pad printing systems that necessitate outstanding durability and precision.

Advantages of Zirconia Pad Printing Rings:

1.Superior Wear Resistance

The elevated hardness of zirconia confers significantly enhanced wear resistance in comparison to conventional metal or plastic materials. Even during prolonged and high-frequency printing operations, zirconia rings manifest minimal wear, leading to an extended service life and diminished maintenance requirements.

2.Outstanding Corrosion Resistance

In pad printing, exposure to various inks and chemicals can readily corrode standard materials. Zirconia’s exceptional chemical stability endows it with robust resistance to most corrosive substances, guaranteeing that the rings maintain consistent and reliable performance over time.

3.Precision Printing Capabilities

Zirconia pad printing rings possess a smooth and uniform surface finish, ensuring accurate and consistent print quality. This renders them particularly apt for applications demanding intricate details and high-quality outcomes, such as those in the electronics and medical device industries.

4.High-Temperature Stability

Zirconia retains its physical properties even under high temperatures, ensuring that printing quality remains unaffected by thermal fluctuations. This characteristic is of crucial importance for pad printing equipment that operates continuously over extended periods.

Zirconia pad printing rings Applications:

Zirconia pad printing rings are ideal for industrial printing operations that require high precision, efficiency, and durability. Key application areas include:

·Consumer Electronics: Precise marking and detailed pattern printing

·Medical Devices: Clear and durable labeling for instruments

·Automotive Industry: Long-lasting part marking and logos

·Luxury Packaging: High-end decorative prints and anti-counterfeiting features

Why Choose Zirconia Pad Printing Rings?

Opting for zirconia pad printing rings augments printing quality while considerably reducing long-term maintenance costs and minimizing downtime. Whether your aim is to enhance product quality or streamline production processes, investing in zirconia pad printing rings constitutes a strategic and cost-effective advancement.

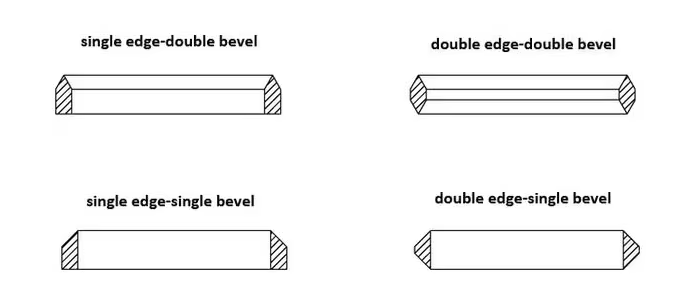

Innovacera Zirconia Ring Type-SD/DD/SS/DS

Zirconia Ring Dimension(Accept customization)

| SPECIFICATION | ||||||||

| OD | ID | H | OD | ID | H | OD | ID | H |

| 25 18 10 | 90 82 12 | 140 131 15 | ||||||

| 50 | 40 | 10 | 92 | 86 | 9.5 | 145 | 135 | 12 |

| 60 50 12 | 94 86 12 | 150 140 12 | ||||||

| 60 | 53 | 12 | 95 | 90 | 5.4 | 155 | 150 | 5.2 |

Zirconia pad printing rings are redefining industrial printing by offering unparalleled efficiency and quality.

Consult with Innovacera

If you want to know how zirconia pad printing rings can transform your operations or any questions, welcome to contact Innovacera at sales@innovacera.com.

Enquiry

Enquiry