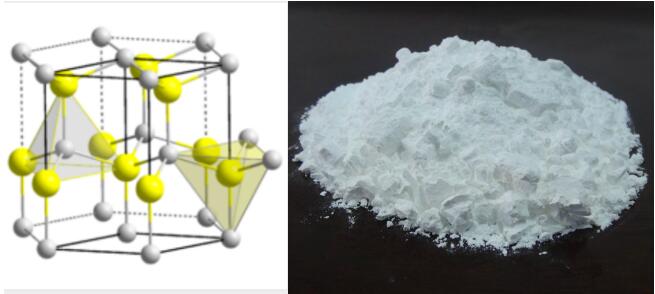

The main crystal phase of aluminium nitride ceramics is aluminium nitride powder, which has the following characteristics:

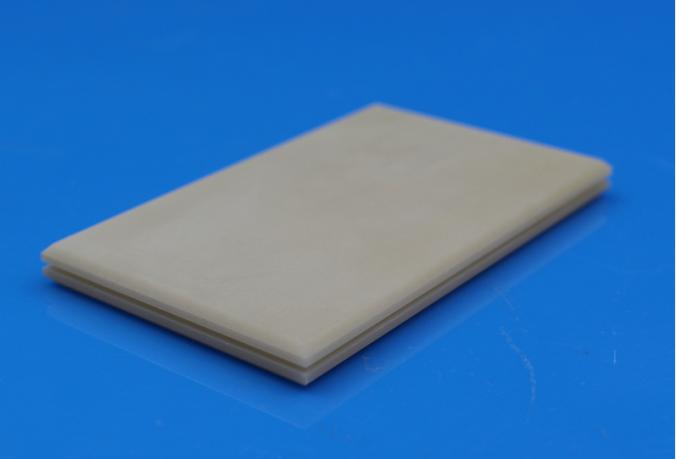

1. What is aluminum nitride?

- Aluminium Nitride (AIN) is one kind has the six-party wurtzite structure form of refractory compounds

- The colour is grey

- Aluminium nitride crystals are covalently bonded compounds with Warzite structure based on [AIN4] tetrahedral structure

- The density of 3.26 g/cm3

- Lattice constant a = 3.11, c = 4.980

- The decomposition temperature is 2480℃ under normal pressure

Advantages of aluminum nitride ceramic materials:

- The strength of room temperature is high and decreases slowly with the increase of temperature

- It has a high thermal conductivity

- Low dielectric constant and dielectric loss

- Low coefficient of thermal expansion

- Good chemical stability and non-toxic

2. Preparation of aluminium nitride powder

The excellent properties of Aluminum nitride ceramics are based on the high quality of their powders. There are many methods to prepare aluminium nitrite powder, such as direct nitridation, carbide reduction process, energetic ball milling, Self-propagating high-temperature synthesis, in situ autoreactive syntheses, plasma chemical synthesis, chemical vapour deposition method, solvothermal method and organic salt cracking.

3. Forming process of Aluminum nitride ceramic

Aluminium nitride ceramic formin process mainly includes: dry forming and wet forming.

1) Dry Formingis suitable for products with simple shapes and high cost, including the following two moulding methods:

- Ordinary die forming

- Cold isostatic forming

2) Wet Formingis suitable for products with complex shapes, low cost and simple process, mainly including the following moulding methods:

- Tape casting

- slip casting

- Injection moulding

- gel casting

Sintering method of aluminum nitride ceramics

- Add sintering assistant

- Spark Plasma Sintering (SPS)

- Microwave Sintering

- Pressureless singtering

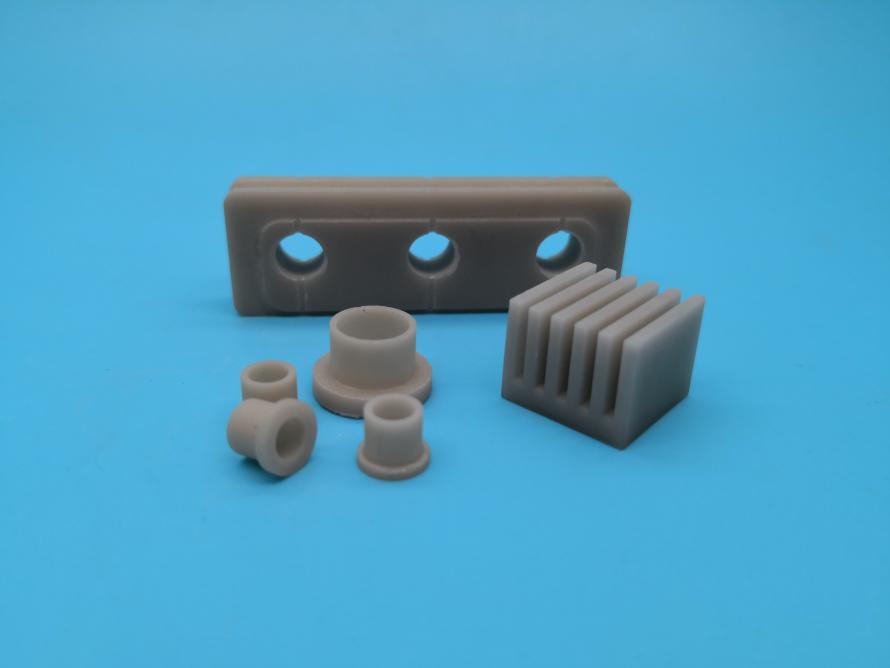

4. Applications of aluminum nitride ceramics

1) Based on higher volume resistivity, insulation strength, thermal conductivity, lower thermal expansion coefficient and dielectric constant, it can be used for Insulation substrates for high-power semiconductor devices, heat dissipation substrates for large-scale and VLSI circuits, and packaging substrates.

2) Based on high acoustic conduction velocity characteristics, can be used in Surface wave device in a high-frequency information processor.

3) Based on high fire resistance and high temperature and chemical stability, can be used to make work under 1300 ~ 2000 ℃ of the crucible

The research of aluminium ammonite ceramics is still in the progress. If the synthesis cost of high-quality powders can be greatly reduced, the densification sintering at low temperature can be realized, and high-quality fluidized substrates can be obtained stably, it will be more and more widely used in the microelectronics industry and other high-tech fields.

INNOVACERA engages in R&D, manufacturing and selling the products of advanced ceramic materials, including Aluminum Nitride, Alumina, Zirconia, Boron Nitride, Silicon Nitride, Machinable Glass Ceramic, and other advanced materials. Through different manufacturing processes, we supply metallized ceramic components, alumina heater, ceramic pump components, and other ceramic components as request.

To find out more about aluminium nitride or any of our other products or services, please feel free to contact us today.

sales@innovacera.com www.innovacera.com

Enquiry

Enquiry