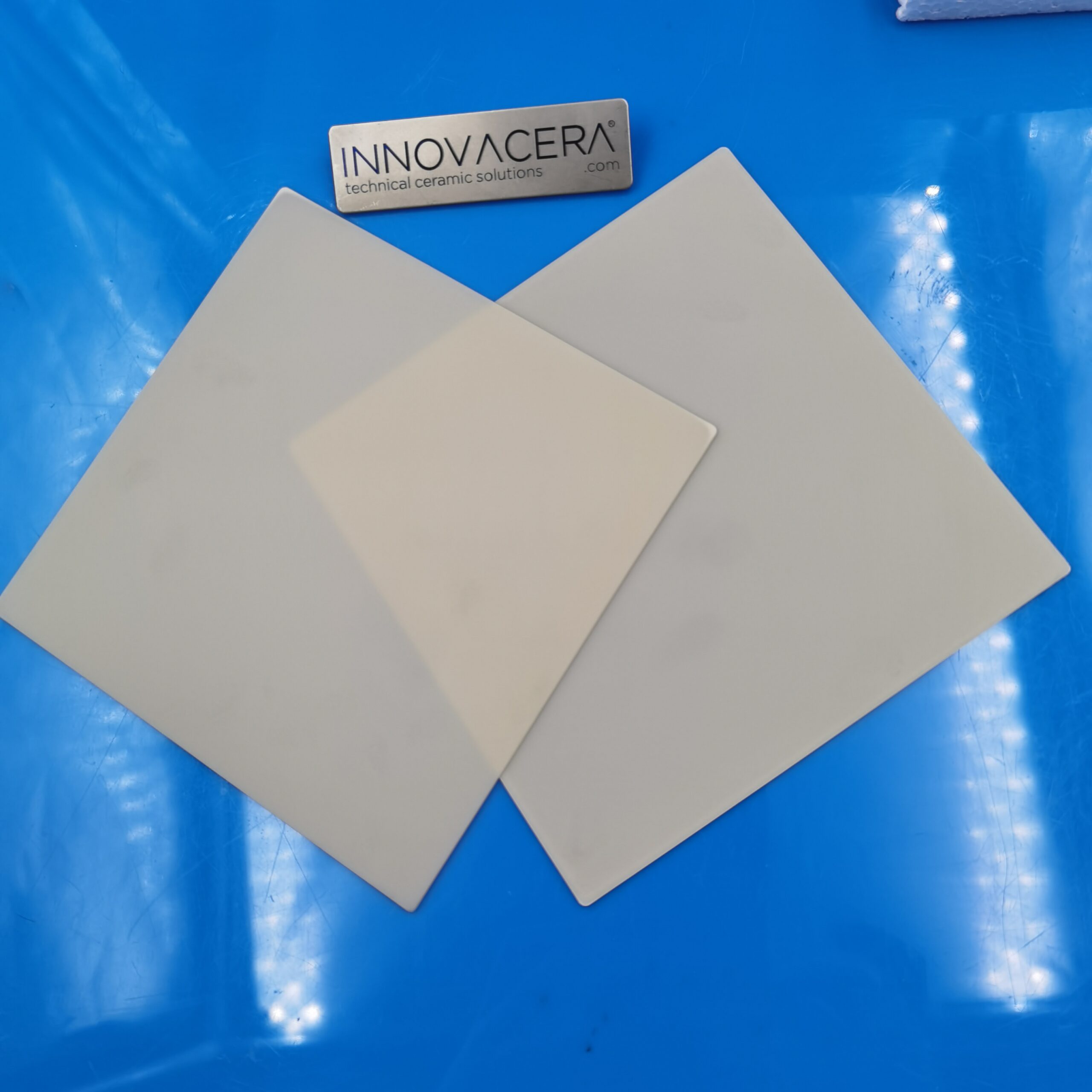

Aluminum nitride products are attracting more and more attention as a new generation of high thermal conductivity materials due to their superior thermal conductivity, high insulation, and thermal expansion rate close to silicon.

Features:

- High thermal conductivity: about 7 times the thermal conductivity of alumina

- Thermal expansion rate: thermal expansion is close to silicon, and the reliability of the mounting of large silicon wafers and heat-resistant cycles

- Electrical characteristics: high insulation, low dielectric coefficient

- Mechanical properties: superior to the mechanical properties of alumina

- Corrosion resistance: stronger than molten metal corrosion resistance

- Purity: low impurity content, non-toxic, high purity

Application:

- High-power transistor module substrate

- High-frequency device substrate

- Heat-radiating insulation board for turn module

- Fixed substrate for semiconductor laser and light-emitting diode

- Hybrid integrated module, the ignition device module

- IC package

- Thermal module substrate

- Some products for semiconductor production equipment

Enquiry

Enquiry