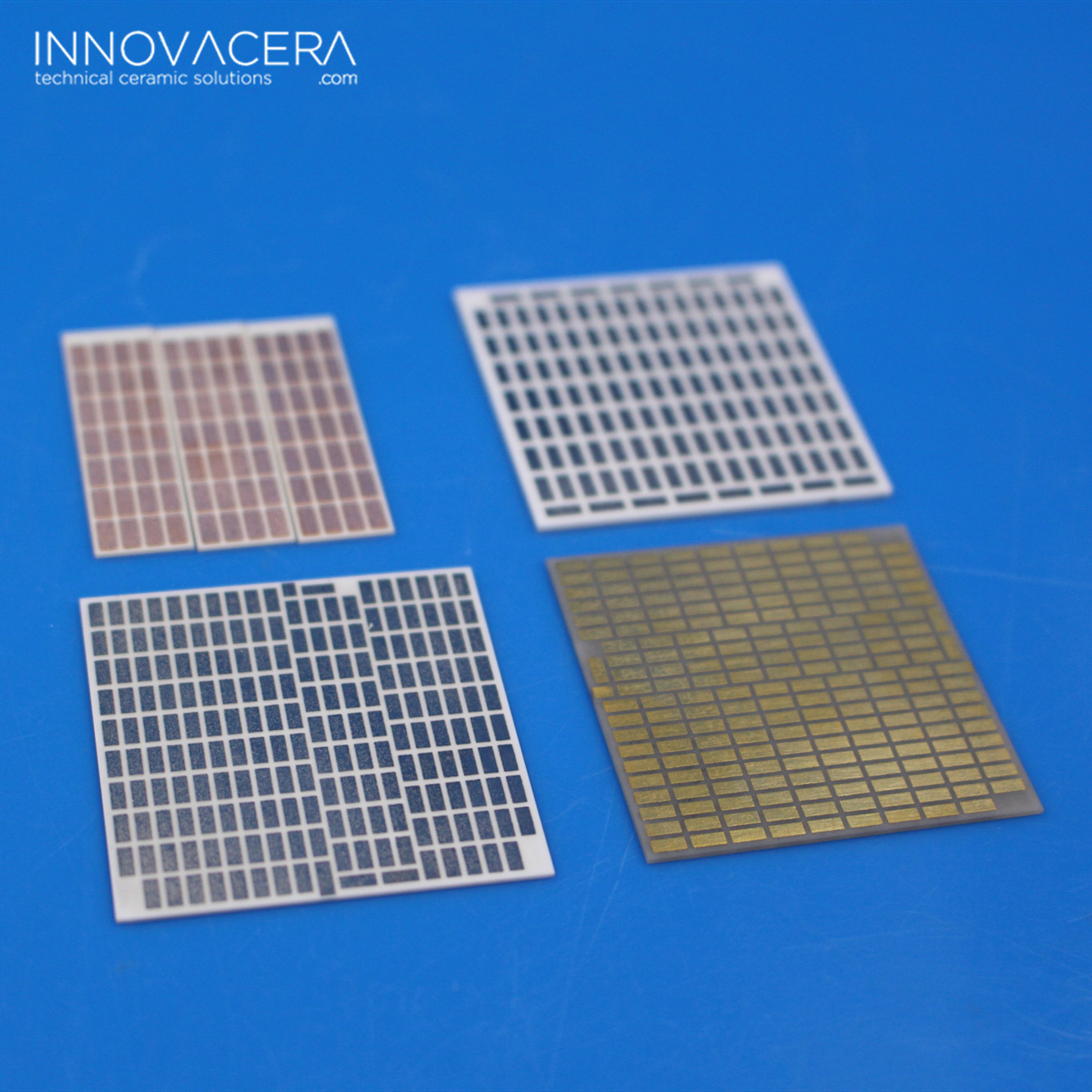

The ceramic-based metalized substrate has good thermal and electrical properties. It is an excellent material for power LED packaging, purple light, and ultraviolet light. It is especially suitable for multi-chip packaging (MCM) and substrate direct bonding chip (COB), etc. package structures.

Classification:

① HTCC and LTCC

HTCC and LTCC belong to earlier developed technologies, but due to the high sintering temperature, the selection of electrode materials is limited, and the production cost is relatively expensive. These factors promote the development of LTCC. Although LTCC reduces the co-firing temperature to about 850°C, however, it has the disadvantages of difficult control such as dimensional accuracy and product strength.

② DBC and DPC

Direct copper coating (DBC) technology is a ceramic surface metallization technology developed mainly based on Al2O3 ceramic substrates and later applied to AlN ceramics. It has been successfully applied in the fields of high-power power semiconductor modules, solar panel components, automotive electronics, aerospace and intelligent power components.

Advantages:

- Good thermal expansion

The ceramic metalized substrate can effectively solve the problem of heat dissipation, thereby alleviating the problem of thermal expansion and contraction of different materials of the components on the ceramic substrate, and improving the durability and reliability of the whole machine and electronic equipment.

- Dimensional stability

- Good heat dissipation

The ceramic material itself has properties such as high thermal conductivity, good heat resistance, high insulation, high strength, and matching with chip materials. It is very suitable as a power device LED packaging ceramic substrate and has been widely used in semiconductor lighting, laser and optical communication, aerospace, automotive electronics, and other fields

If you have more interesting, pls consult with us.

What Are The Advantages Of Metallized Ceramic Substrates In LED Packaging

Enquiry

Enquiry