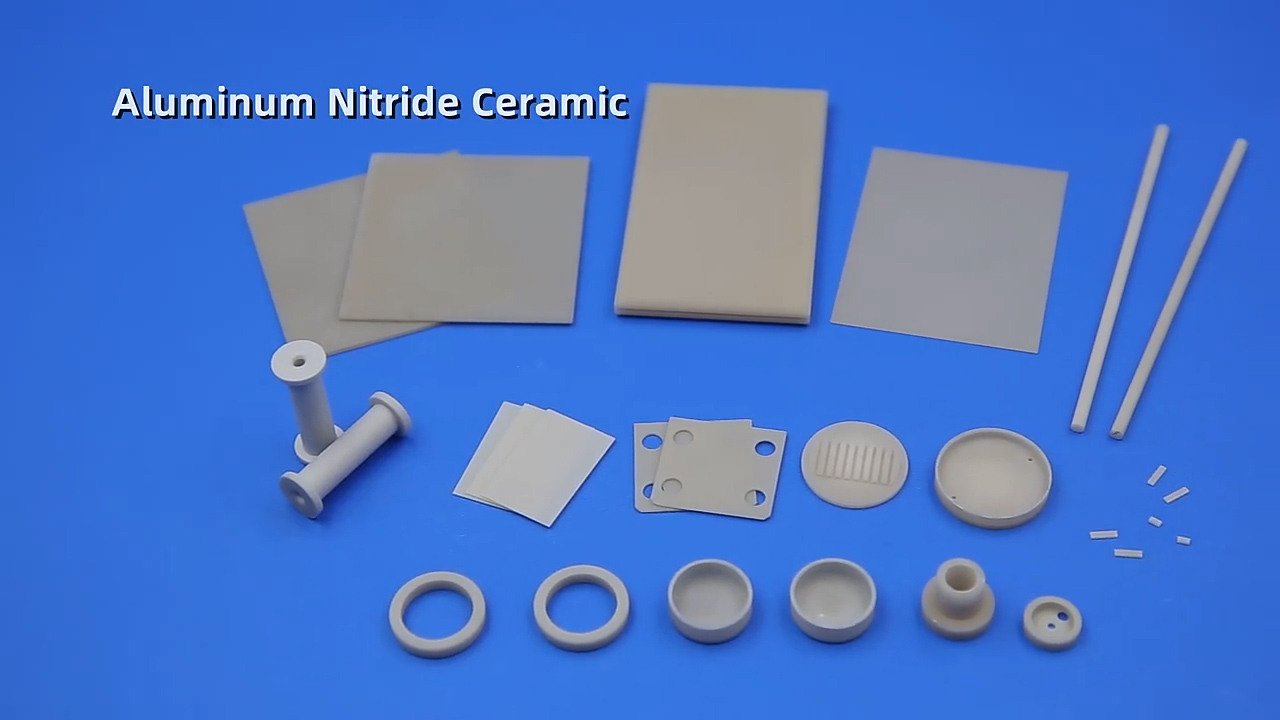

First of all, let’s overview AlN Ceramics

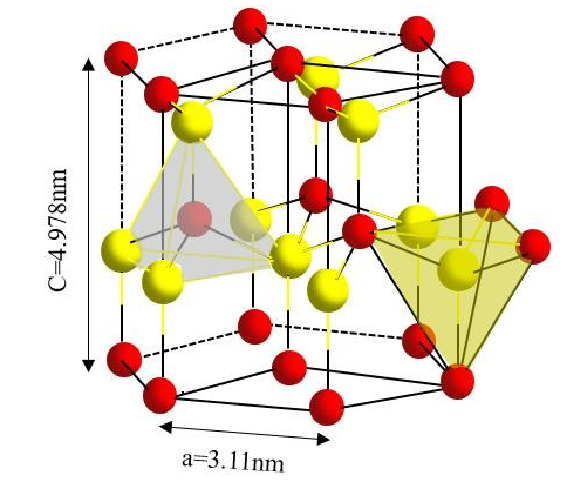

AlN is a covalently bonded compound with a stable structure and hexagonal wurtzite structure without the existence of other allotypes. Its crystal structure is the AlN4 tetrahedron produced by the disproportionation of aluminum atoms and adjacent nitrogen atoms as the structural unit; the space group is P63mc, which belongs to the hexagonal crystal system.

The main features of aluminum nitride ceramics:

(1) High thermal conductivity, which is 5-10 times that of alumina ceramics;

(2) The thermal expansion coefficient (4.3×10-6/℃) matches the semiconductor silicon material (3.5-4.0×10-6/℃);

(3) Good mechanical properties;

(4) Excellent electrical properties, with extremely high insulation resistance and low dielectric loss;

(5) Multi-layer wiring can be performed to achieve high density and miniaturization of packaging; (6) Non-toxic, good Conducive to environmental protection.

Various factors affecting the thermal conductivity of AlN ceramics

At 300K, the theoretical thermal conductivity of AlN single crystal material is as high as 319W/(m K), but in the actual production process, due to the purity of the material, internal defects (dislocations, pores, impurities, lattice distortion), grain The thermal conductivity is also affected by various factors such as orientation and sintering process, which are often lower than the theoretical value.

In summary:

Selecting the appropriate sintering aids in the composite system can achieve a lower sintering temperature of AlN and effectively purify the grain boundaries, and obtain AlN with higher thermal conductivity.

What Are The Factors That Affect The Thermal Conductivity Of AlNCeramic Substrates

AlN Schematic diagram of the crystal structure

Enquiry

Enquiry