Innovacera heating element is the PROCESS of MCH (Metal Ceramics Heater). It is the material of tungsten, molybdenum, molybdenum, manganese, and other high melting points Metal heating resistance paste is printed on 92 ~ 96% alumina flow ceramic green billet according to the requirements of heating circuit planning, with 4 ~ 8% sintering agent multi-layer superposition. At 1500 ~ 1600°C under high temperature burning into one body has the advantages of corrosion resistance, high temperature resistance, long life, high efficiency and energy saving, uniform temperature, good thermal conductivity, thermal compensation speed, and does not contain lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyl, polybrominated diphenyl ethers, and other harmful substances, in line with the European Union RoHS environmental protection requirements. It is another generation product after alloy heating wire and PTC heating element.

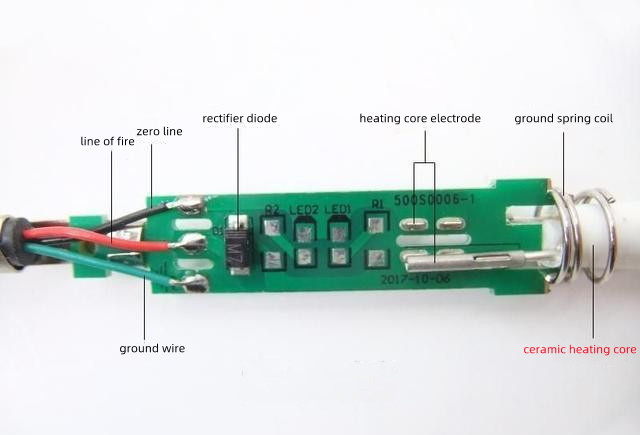

First, let’s make simply introduce the Soldering Iron. See the picture below for details.

(1)Soldering Iron

(2)Disassembly view (front)

(3)Disassembly view (rear)

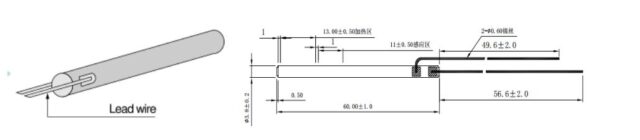

And then taking a look at the structure of the ceramic heating core. The outer diameter of the heating core is 3.8mm, which is suitable for a variety of internal heating soldering irons. There is a groove in the outer packaging ceramics, which is beneficial to the sintering of the manufacturing process and the elimination of working thermal stress. At the same time, please pay attention to the terminal at the root, which is relatively firm.

Brief introduction of ceramic heating core:

1) Main specifications:

Size: D3.8*60mm; D3.8*ID1.5*60mm .

Voltage: A:110V/130ohm, resistance deviation: ±10%

B: 220V/420ohm, resistance deviation: ±10%, can rise to 600-700°C power about 30W Heating area 25mm.

2) structure

In addition to the D3.8*60mm specification, we also have a variety of other specifications. Customization is also available.

Enquiry

Enquiry