VCSEL (Vertical Cavity Surface Emitting Laser) laser diodes have become increasingly popular in the telecommunications, sensing, LIDAR, and optical interconnect industries due to their high efficiency, low power consumption, and high-speed modulation capabilities. One key factor in the performance and reliability of VCSEL laser diodes is the substrate material on which they are grown.

Traditionally, VCSEL laser diodes have been grown on gallium arsenide (GaAs) substrates. However, GaAs have some limitations such as a high thermal expansion coefficient and relatively low thermal conductivity, which can lead to thermal management issues and reliability problems. This is where DPC (Direct Bonded Copper) come into play.

DPC-Why VCSEL Laser Diodes Should Use DPC Ceramic Substrates

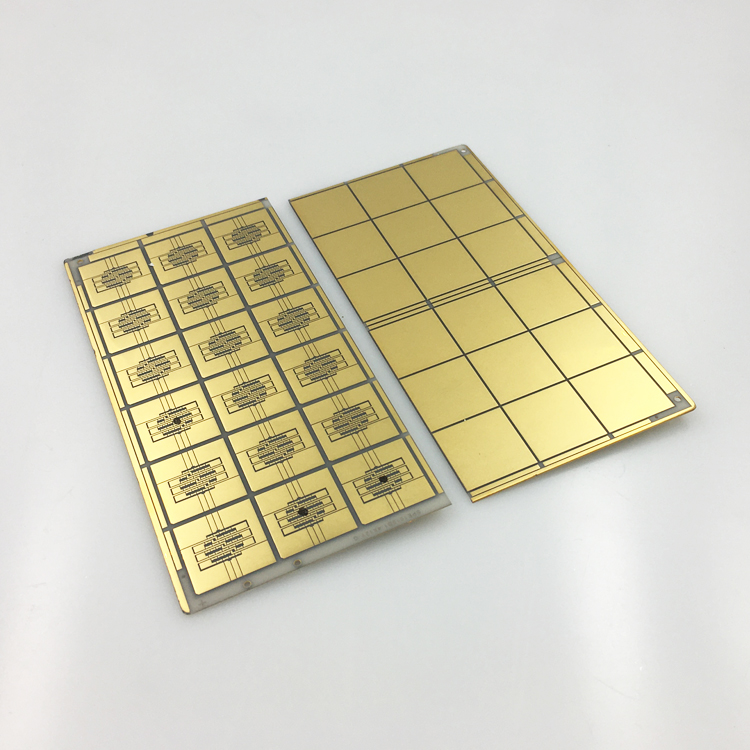

DPC ceramic substrates are an ideal material for growing VCSEL laser diodes due to their high thermal conductivity, low thermal expansion coefficient, and excellent mechanical properties. The direct bonding process used to create DPC substrates ensures that the copper layer is tightly bonded to the ceramic layer, providing excellent thermal management properties.

In addition, DPC ceramic substrates have a coefficient of thermal expansion (CTE) that is well-matched to the epitaxial layers of the VCSEL laser diodes. This ensures that the diodes remain stable and reliable over a wide range of temperatures, making them suitable for use in a variety of applications.

Using DPC ceramic substrates can also improve the performance of VCSEL laser diodes by reducing the threshold current and increasing the output power. This is due to the excellent thermal management properties of the DPC substrate, which can dissipate heat more efficiently and prevent thermal runaway.

In summary, the use of DPC ceramic substrates in VCSEL laser diodes offers many advantages over traditional GaAs substrates, including improved thermal management, reliability, and performance. As the demand for high-speed, low-power laser diodes continues to grow, DPC ceramic substrates will become an increasingly important component in the production of VCSEL devices.

If you’re looking for a reliable DPC for VCSEL laser diodes. Contact us today to learn more about our full range of products and how we can help you

Enquiry

Enquiry