AMB (Active Metal Brazing) is for joining ceramics that are not wetted by ‘conventional’ brazes.

Applying active metal like titanium is added to the braze alloy, to achieve a chemically reacts with the surface of the parent ceramic.

Due to the coefficient of thermal expansion of Al2O3 (7.1 ppm/K), Si3N4 (2.6 ppm/K), and AlN (4.7 ppm/K) is close to that of silicon (4 ppm/K), Direct Bond Copper (DBC) and AMB are suitable substrates for robust packaging of bare dice since such assemblies.

AMB is a promising thick film technology that can be applied to Power Electronics, Automotive Electronics, Home Appliances, Aerospace, and Others.

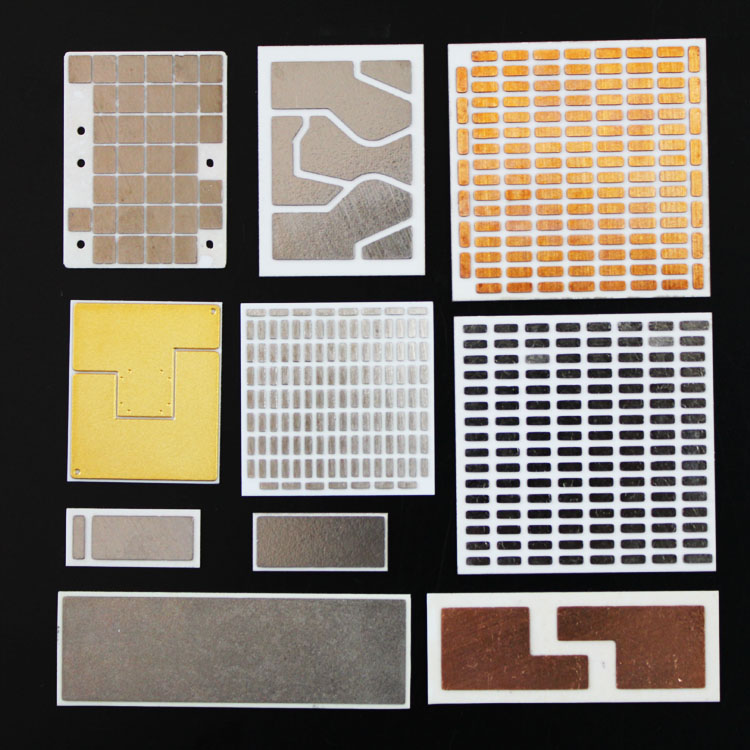

INNOVACERA provides DBC, DPC, and AMB technology for customized ceramic substrates, welcome to consult more.

Active Metal Brazed (AMB) Ceramic Substra

Enquiry

Enquiry